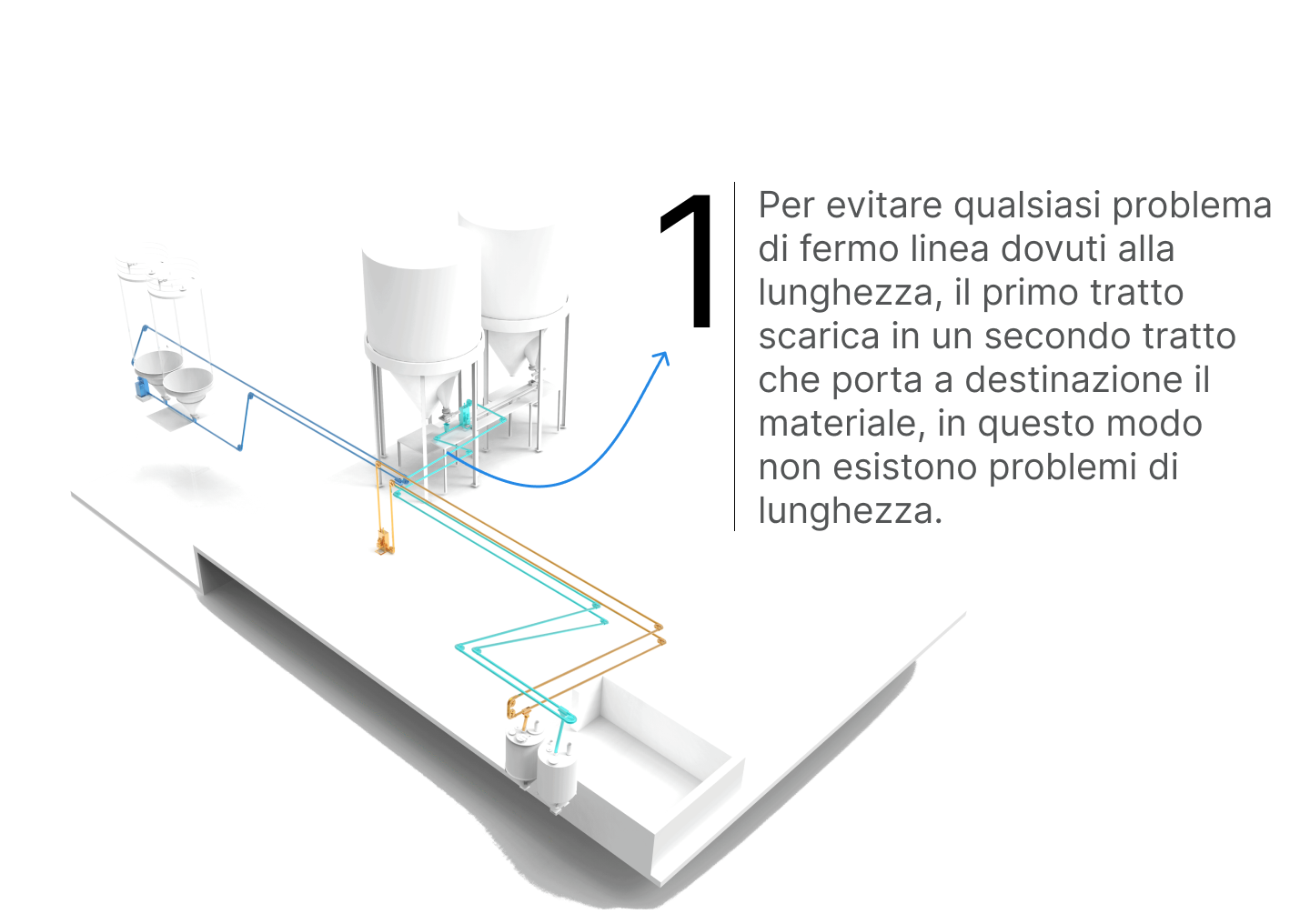

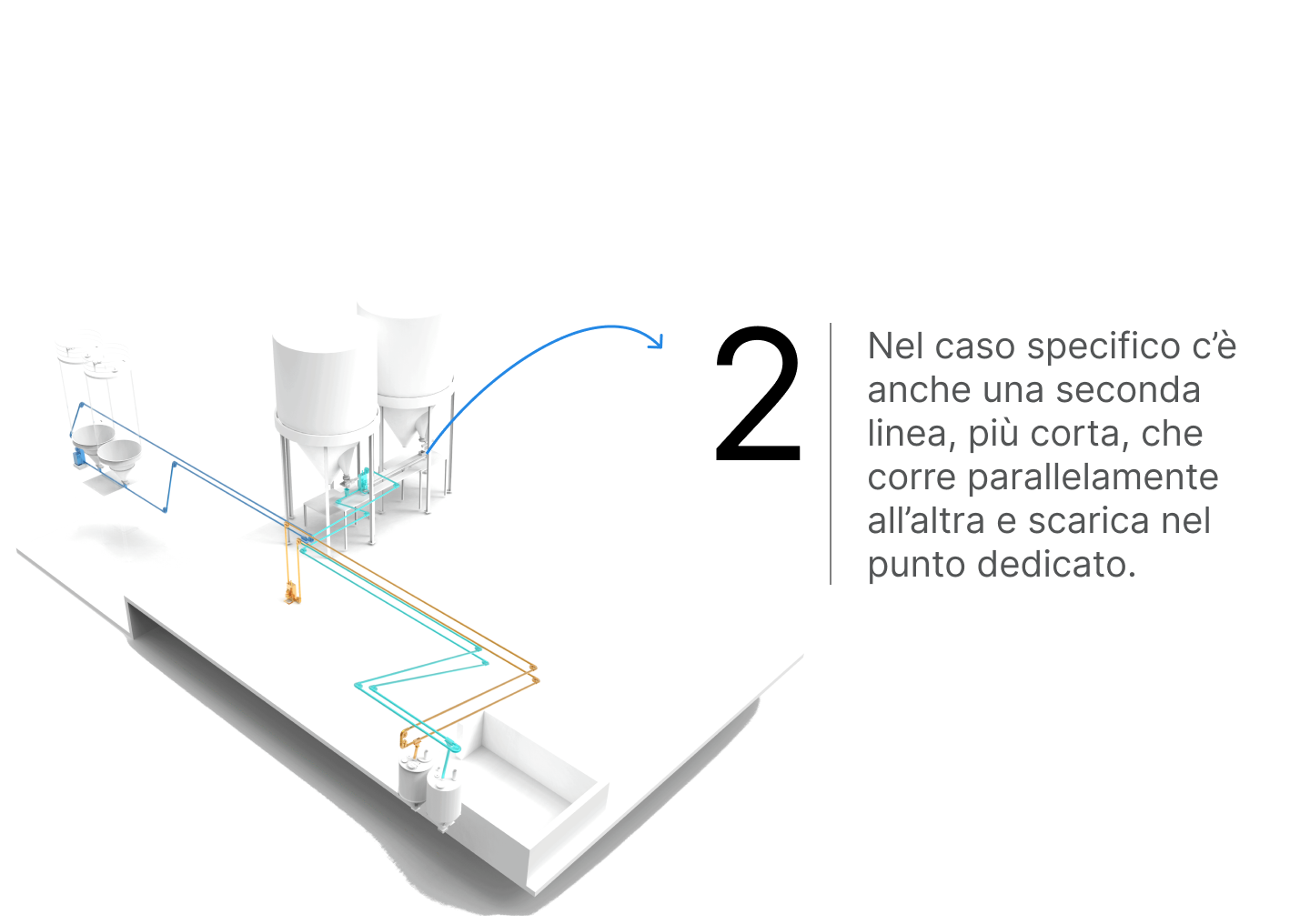

The distinctive feature of this system is its length. It consists of three mechanical conveyors (UNI 168) equipped with vertical drive units that transport material over a distance of more than one hundred meters. The loading process is controlled by two pairs of rotocells positioned under the silos, which feed material into two painted carbon steel mechanical conveyors. These two separate lines discharge at a designated point. One of the lines is doubled to ensure continuous flow along the entire circuit.

Il carico è controllato da due coppie di rotocelle disposte sotto i silos che immettono il materiale in due convogliatori meccanici in ferro verniciato. Le due linee distinte scaricano in un punto dedicato.

Una linea è doppia per assicurare la percorrenza lungo tutto il circuito.

© 2023 Hiway S.R.L – p.iva: 03609640168

Privacy Settings

This website uses cookies to improve your experience while you navigate through the website.

View the Cookie Policy View the Personal Data Policy