Mechanical Conveyor

Hiway mechanical distributing conveyors are ideal for the transportation and distribution of various types of powders and granules from one or more loading points to one or more drops and they can be extended over 200 meters. These systems are powered by one drive unit that moves the disc chain into the tubes, mechanically dragging the material due to the linear speed exerted on it.

The material is discharged gravitationally through interception valves, which can be operated manually or pneumatically and are positioned along the transport pipeline.

This solution is particularly suitable for long distances, and the slow speed of the chain enables delicate handling of even the most fragile materials. Like every Hiway’s system, the mechanical conveyors ensure no dust leakage into the environment, the ability to transport products with different specific weights, and ease of integration into existing systems due to their modularity and low energy consumption.

[uni]

Mechanical Conveyor

qualità e innovazione

I convogliatori distributori meccanici HiWay sono ideali per il trasporto e la distribuzione di polveri e granuli di varie tipologie in diversi punti di un circuito.

Questo sistema è azionato da un gruppo di traino dotato di un meccanismo di tensionamento automatico della catena, che consente ai dischi di trascinare meccanicamente il materiale grazie alla velocità lineare impressa dalla catena.

Lo scarico del materiale avviene in modo gravitazionale attraverso valvole d’intercettazione, che possono essere comandate manualmente o pneumaticamente e sono posizionate lungo la tubazione di trasporto.

Questa soluzione è particolarmente adatta per lunghi tragitti e la bassa velocità della catena permette di trattare delicatamente anche i materiali più fragili.

Come tutti gli impianti HiWay, i convogliatori meccanici garantiscono l’assenza di fuoriuscite

di polvere nell’ambiente, la capacità di trasportare prodotti con differenti pesi specifici e la facilità di integrazione in impianti già esistenti grazie alla loro modularità.

cmc

Main Construction Materials

- Carbon steel

- AISI 304 or AISI 316 stainless steel

- Carbon steel

- AISI 304 or AISI 316 stainless steel

- Aluminum Casting

- Cast iron

- Aluminum (with food certification)

- Carbon steel

- AISI 304 or AISI 316 stainless steel

- Nylon

- Glass filled nylon

- Polyester

Technical Specification

Main plant components

Load

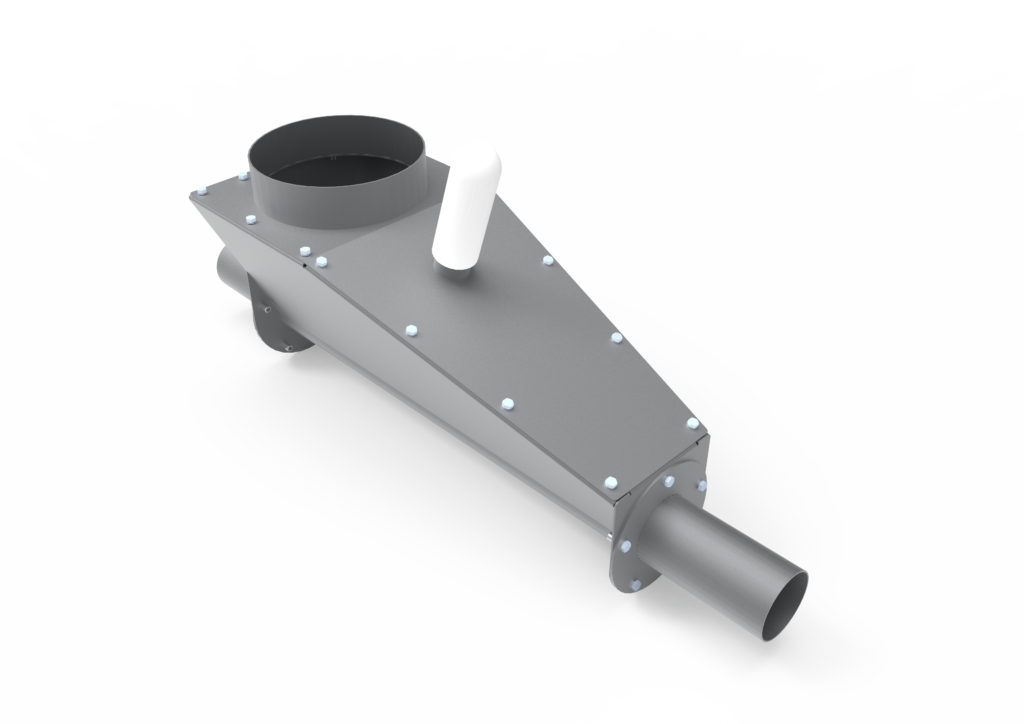

LOADING SPOUT (LHG)

Simple and flexible gravity inlet, suitable for all conveyors.

GRAVITY DOSING HOPPER (TRB)

Loading hopper with hatch for dosing the material entering the line.

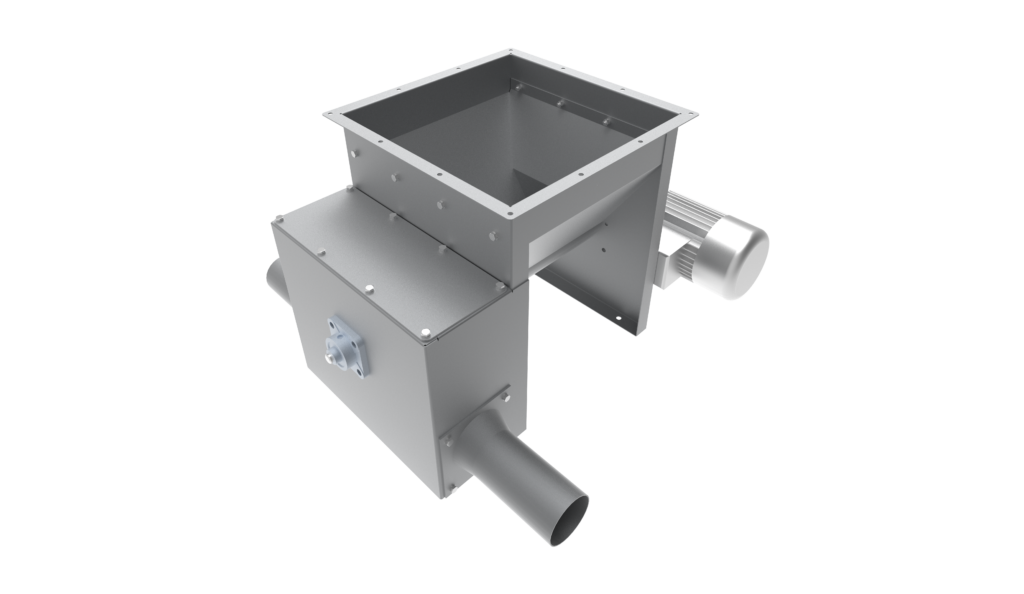

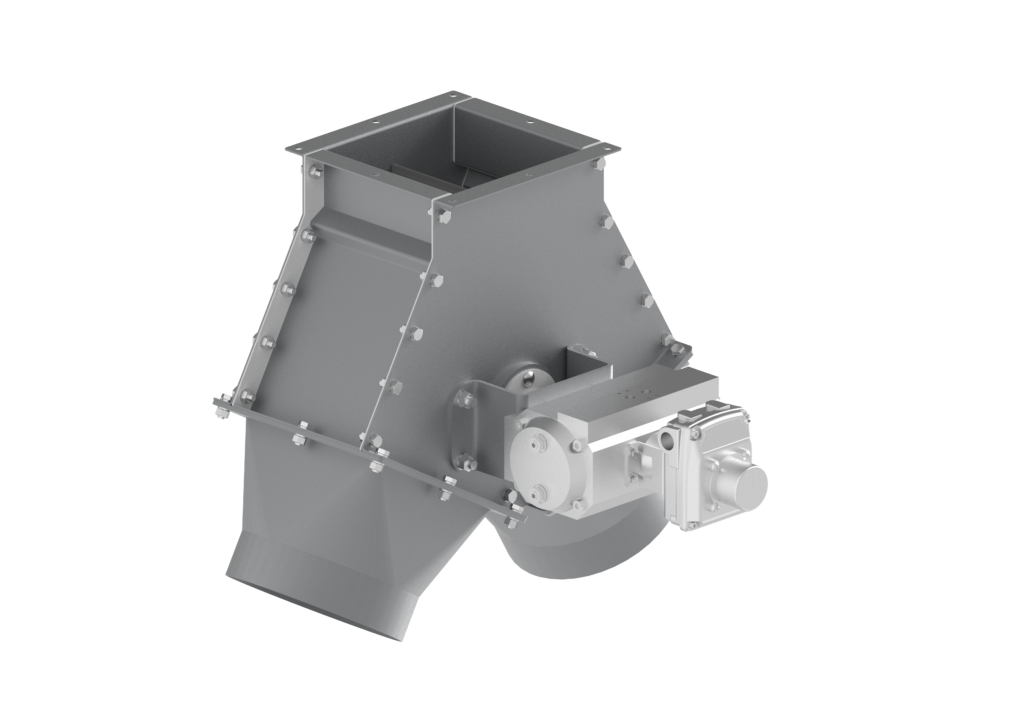

MOTORIZED HOPPER (LHM)

Hopper equipped with motorized screw for the metered material insertion

into the line.

Unload

FREE UNLOADING

Simple, compact and economical, it

allows the descent of the material

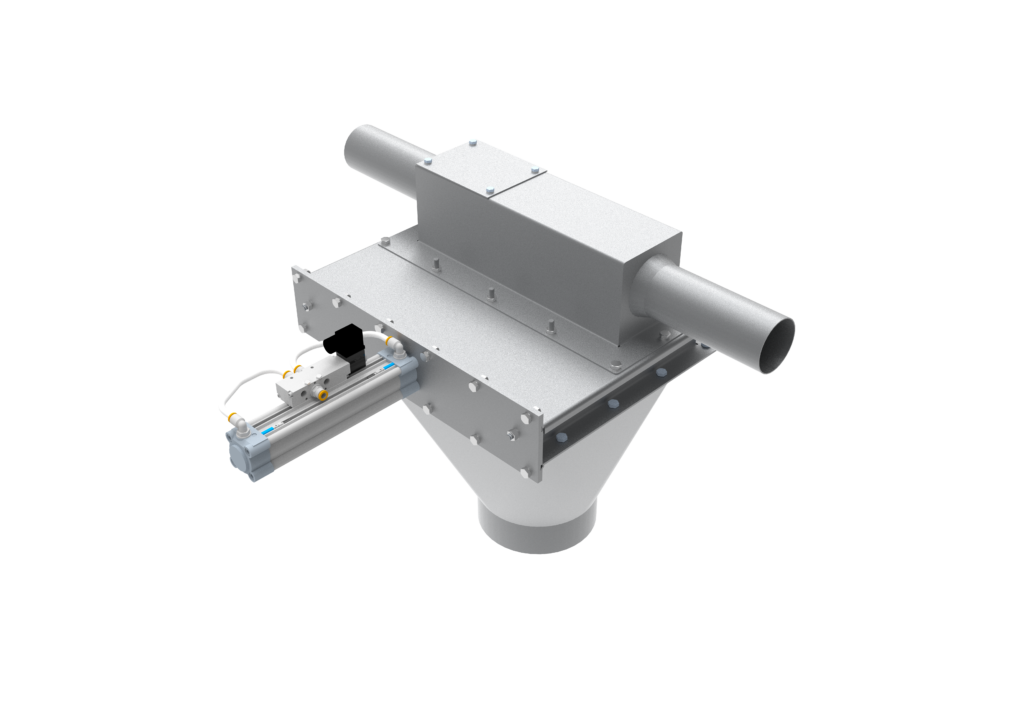

DISCHARGE WITH KNIFE GATE CLOSURE

This discharge allows automatic

selection for the distribution of

the material and is activated by a

pneumatic damper.

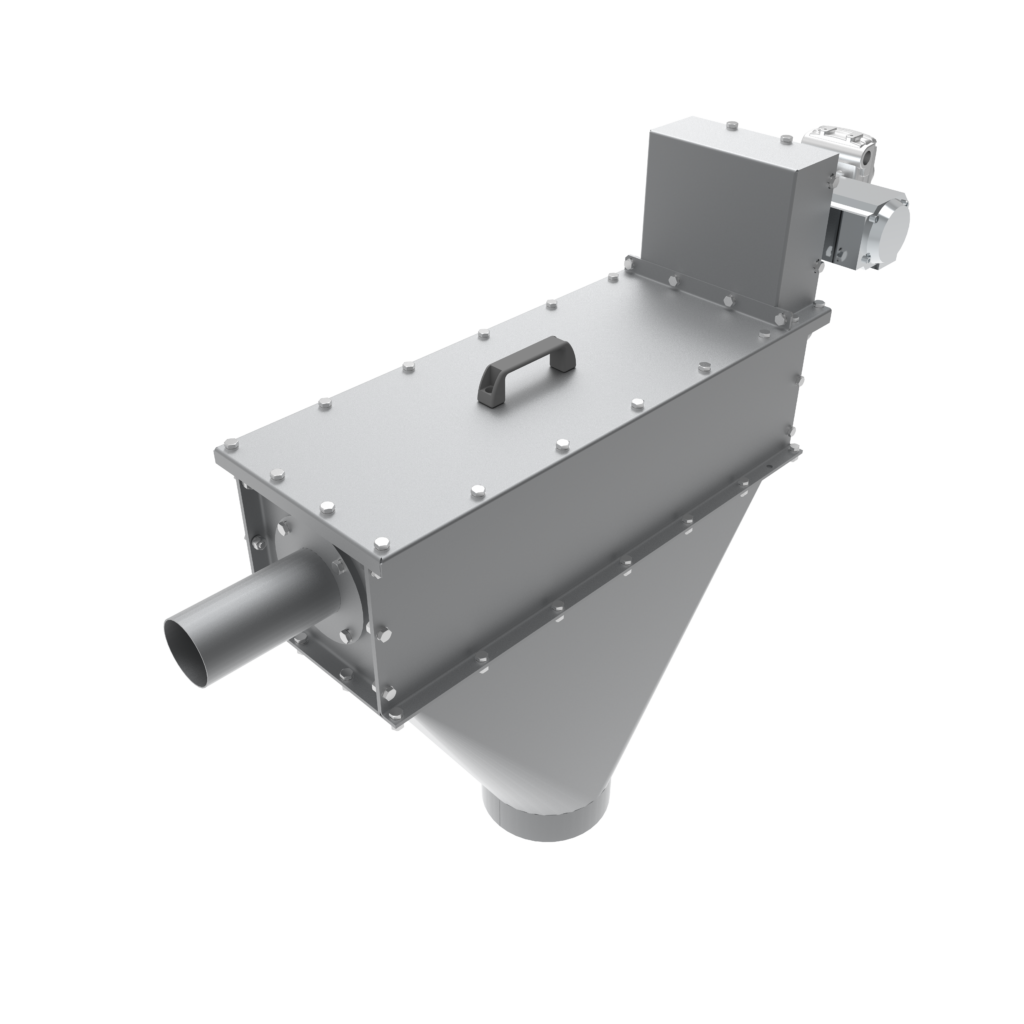

ROTARY DISCHARGE

The rotary discharge, which can

be operated automatically (both

pneumatically and electrically),

allows the selective descent of the

material with simple or hermetic

closure.

Components

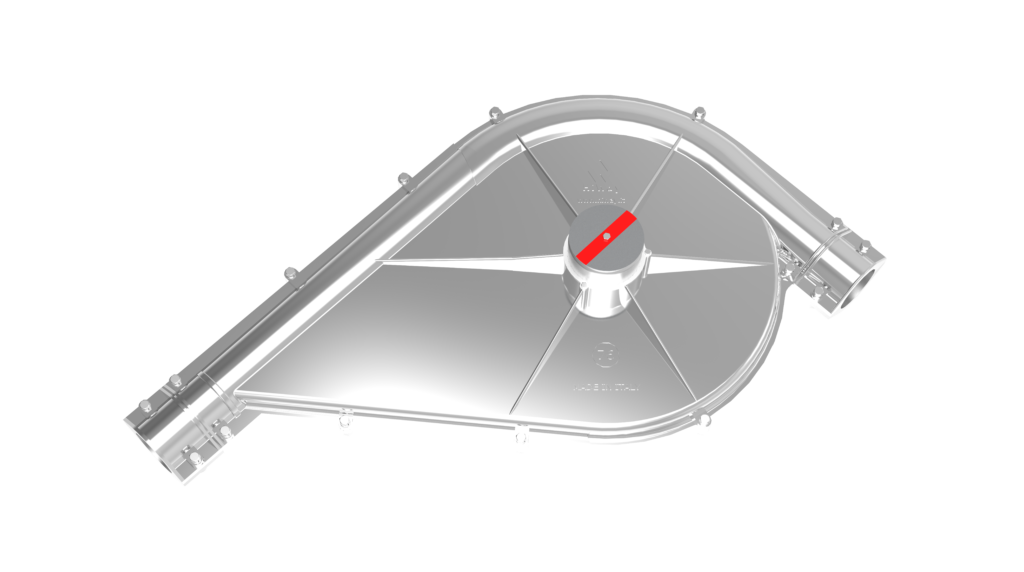

IDLE CURVE

All UNI system corners are non-

motorized, and standard models come

with angles of 45°, 90°, and 180°. Other

angles are defined based on

specific requirements.

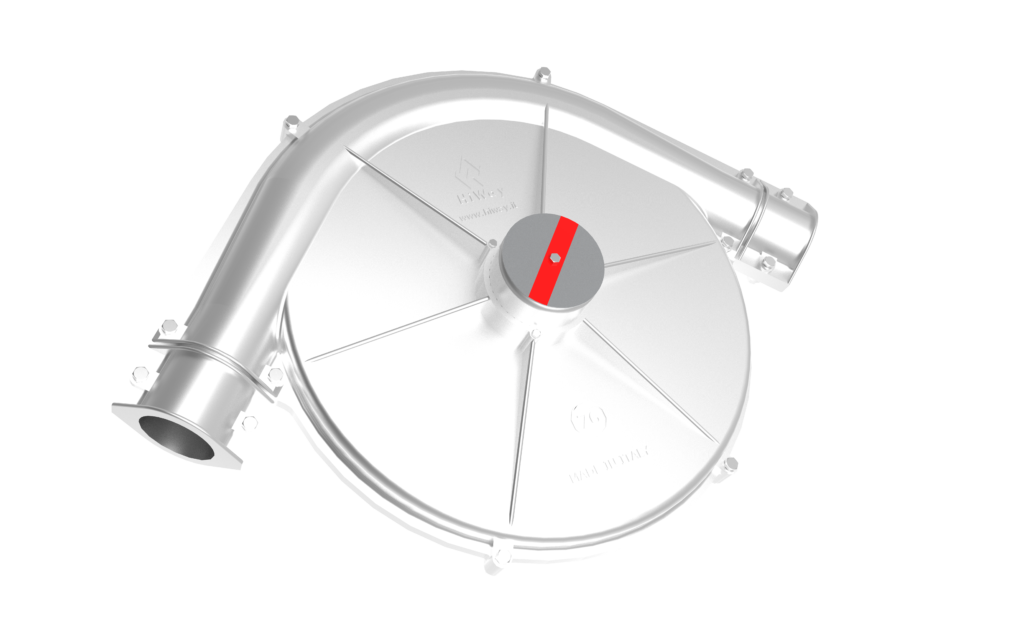

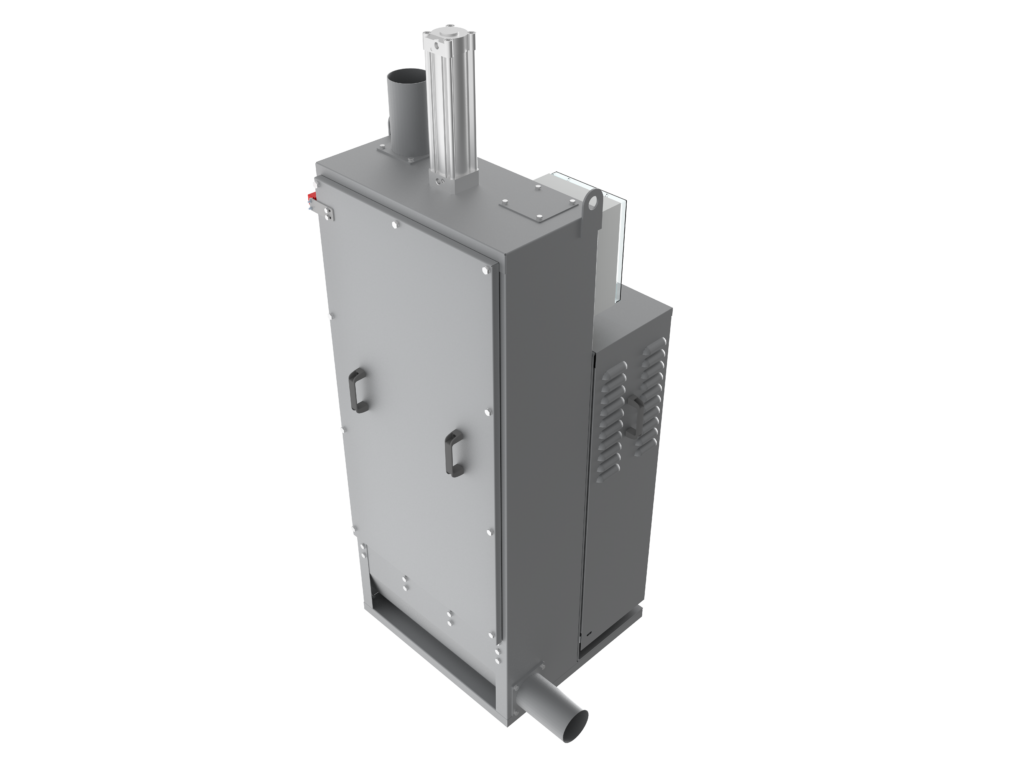

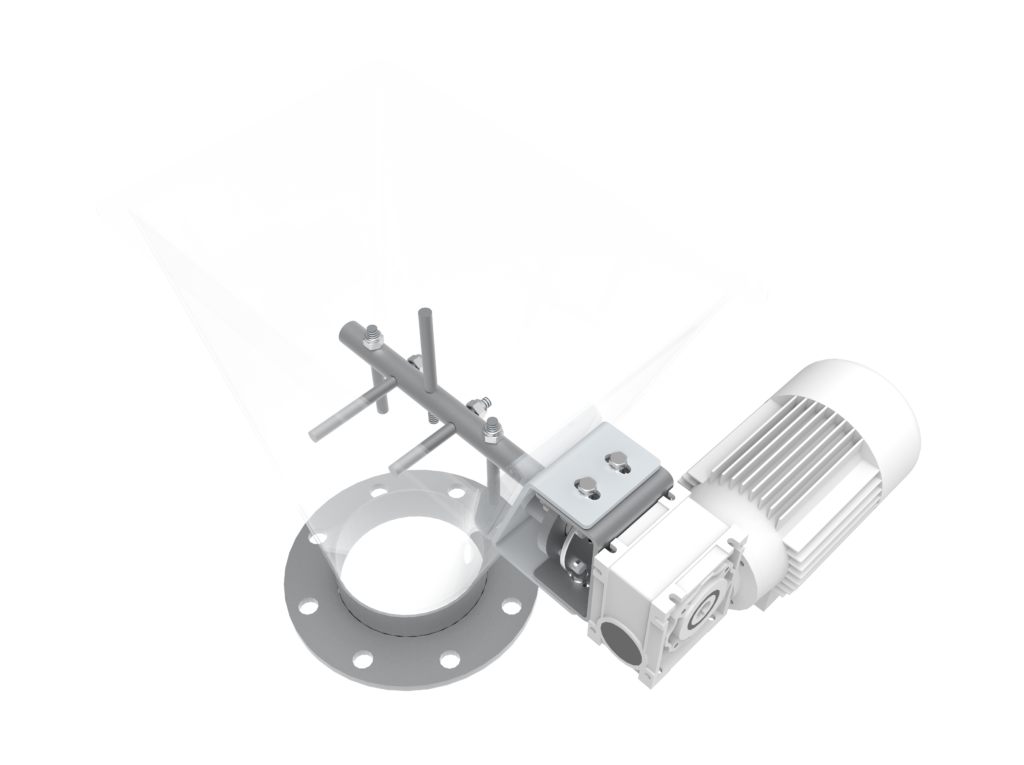

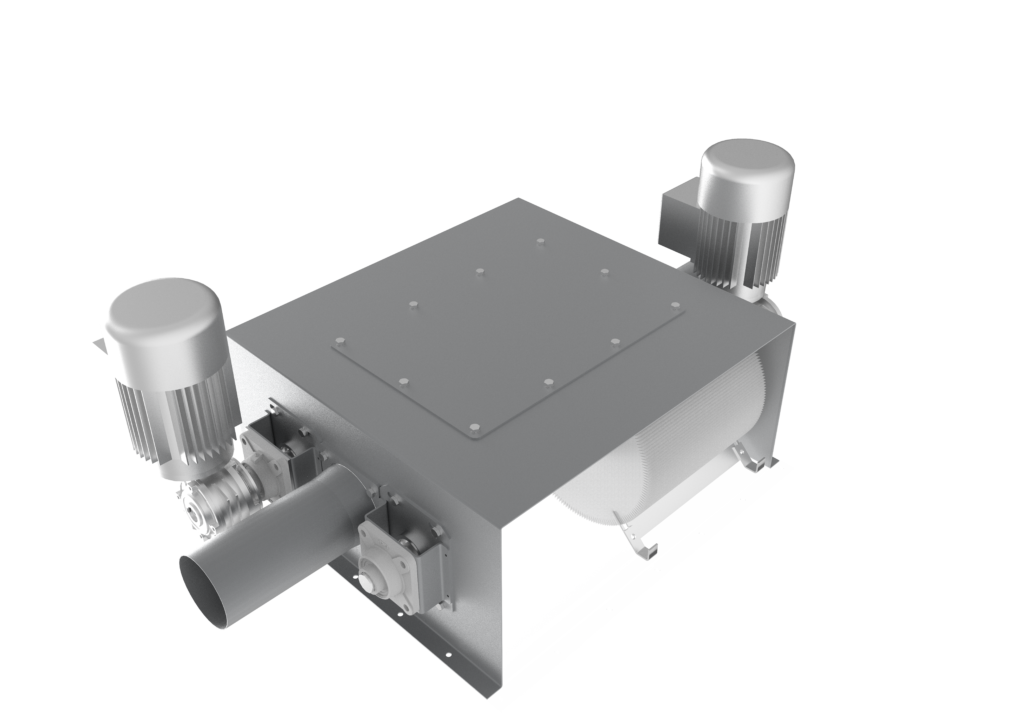

DRIVE UNIT

The drive units impart motion to the chain within the system. A large-sized door allows the inspection of the interior. They can be installed in both indoor and outdoor environments. Chain tensioning is achieved through a spring or pneumatic piston.

TANGENT CURVE

90° idle curve to facilitate the material flow

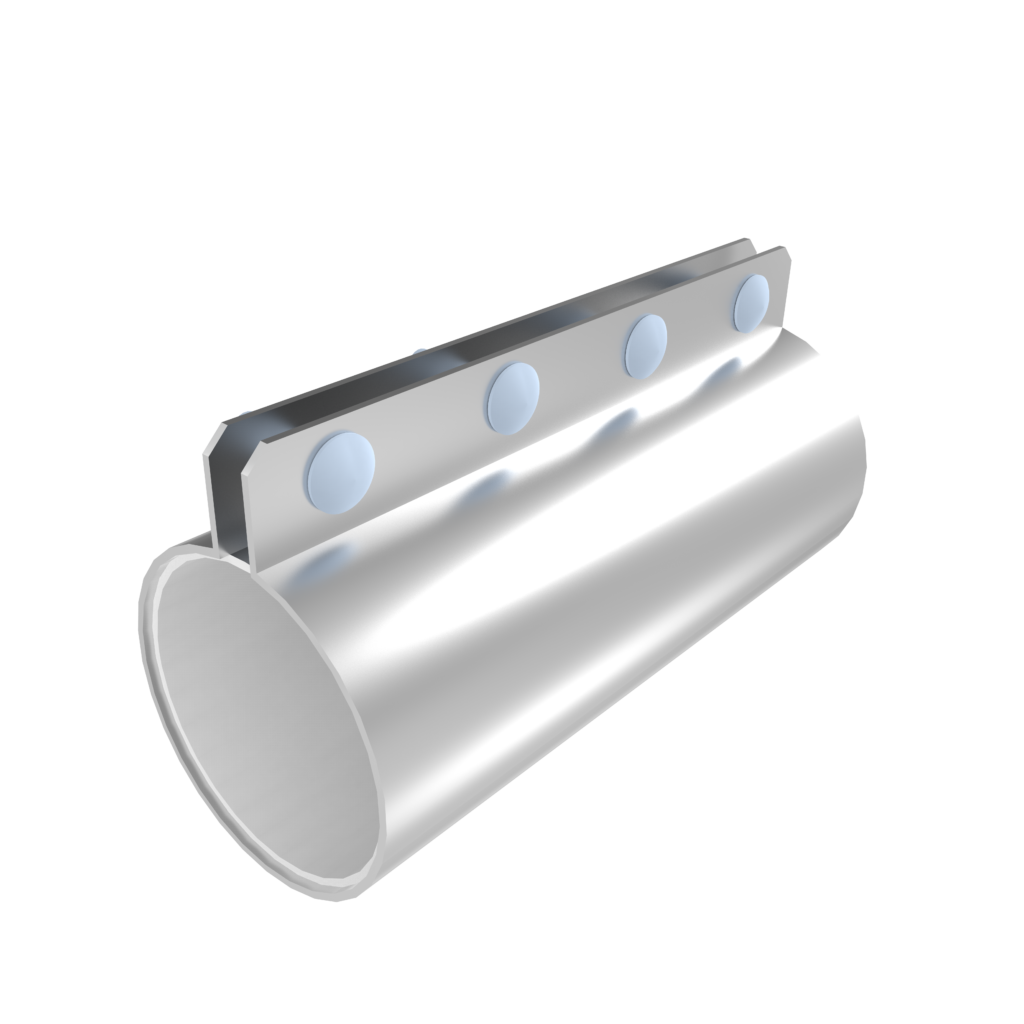

PIPE JOINT

They are quick to install and guarantee the robustness of the connection as well as the prevention of dust escaping into the environment and electrical continuity for earthing.

Accessories

DIVERTER VALVE

Pneumatically operated valve that directs the material in one or the other direction.

BRIDGE BREAKER

Special machine to avoid the formation of bridges in the material

ROTARY BRUSHES

A set of rotating brushes for

complete chain cleaning.

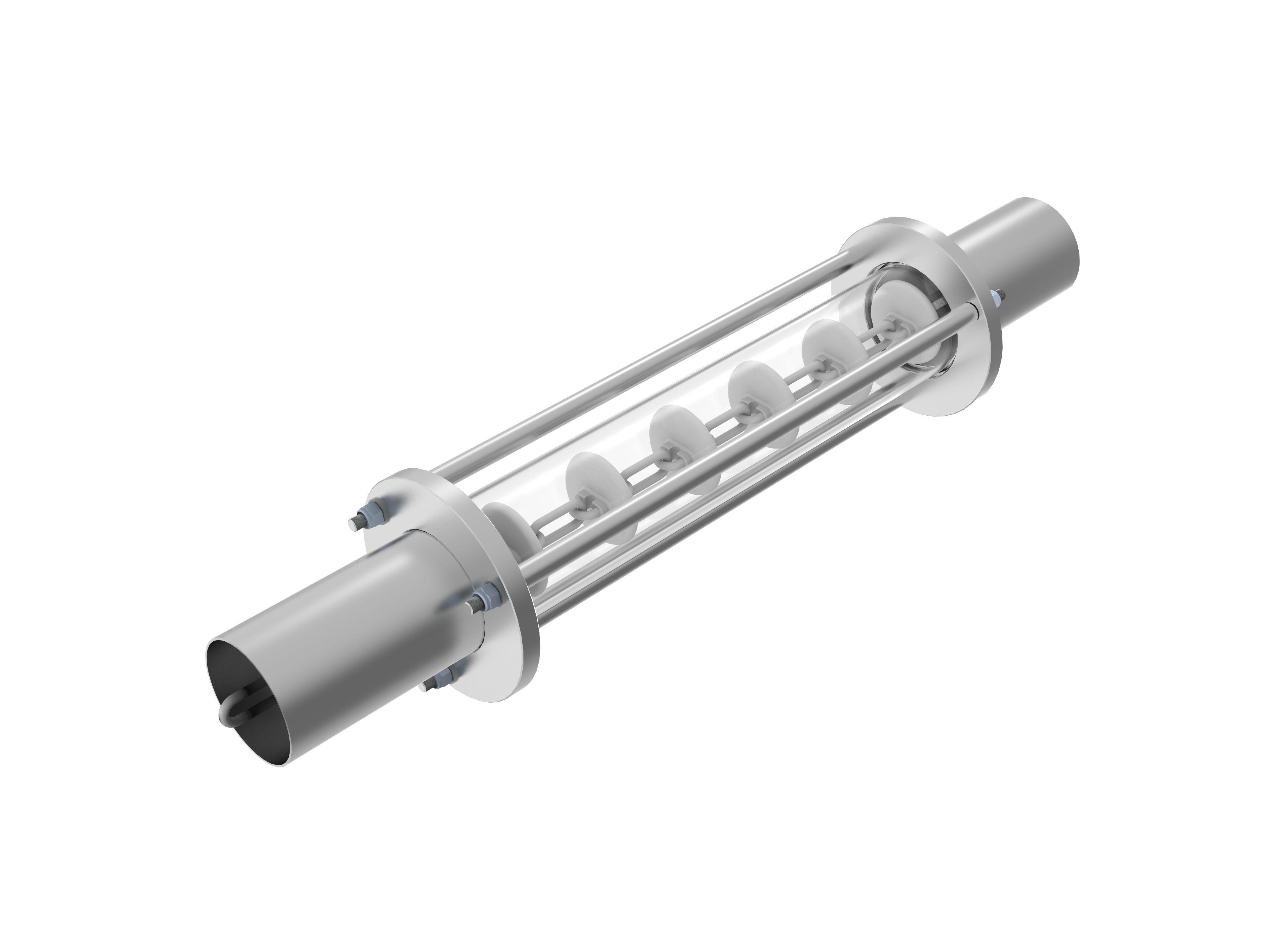

SIGHT GLASS

Optional transparent tube section to allow inspection of the rope or chain inside the line.

Applications