Bag cutters are designed to safely empty bags of various sizes and reduce the dispersion of dust into the environment, ensuring safety in the workplace. This equipment can be installed with one hood connected to an extraction system to avoid dust dispersion.

There is also a net that acts as a support surface for the bag and ensures the operator’s safety during the emptying operations.

Depending on the danger and specific needs of the customer, various models are available, some of which avoid direct contact between the operator and dust, guaranteeing greater protection and safety.

BAG CUTTER STATIONS

BAG CUTTER

Bag cutters are designed to safely empty bags of various sizes and reduce the dispersion of dust into the environment, ensuring safety in the workplace. This equipment can be installed with one hood connected to an extraction system to avoid dust dispersion.

There is also a net that acts as a support surface for the bag and ensures the operator’s safety during the emptying operations.

Depending on the danger and specific needs of the customer, various models are available, some of which avoid direct contact between the operator and dust, guaranteeing greater protection and safety.

MAIN LAYOUTS

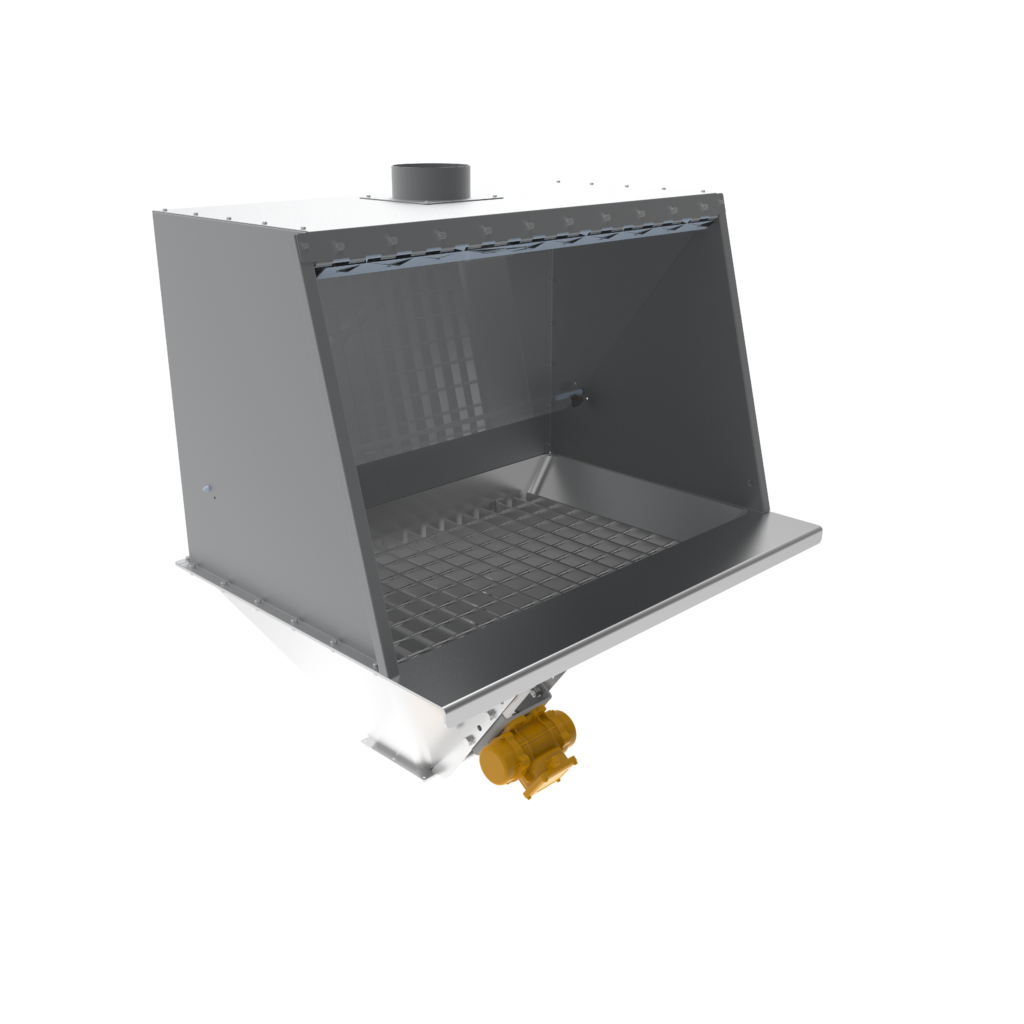

MANUAL BAG CUTTER

Station for manual bag cutting with discharge into the line.

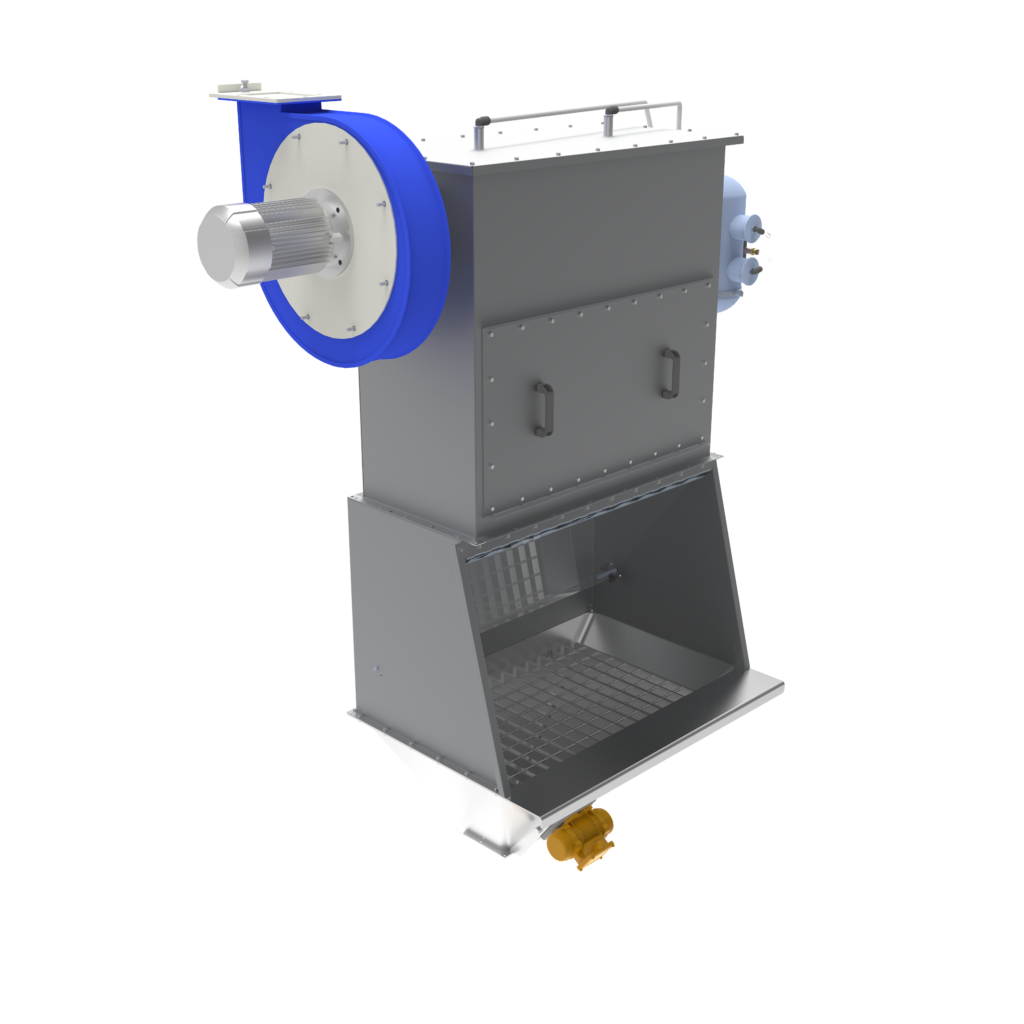

BAG CUTTER WITH AUTOMATIC DOOR

Station featuring both suction and an underlying screw conveyor to feed the material into the line. Its special feature is an automatic door for closing the opening where the bag with the material is inserted.

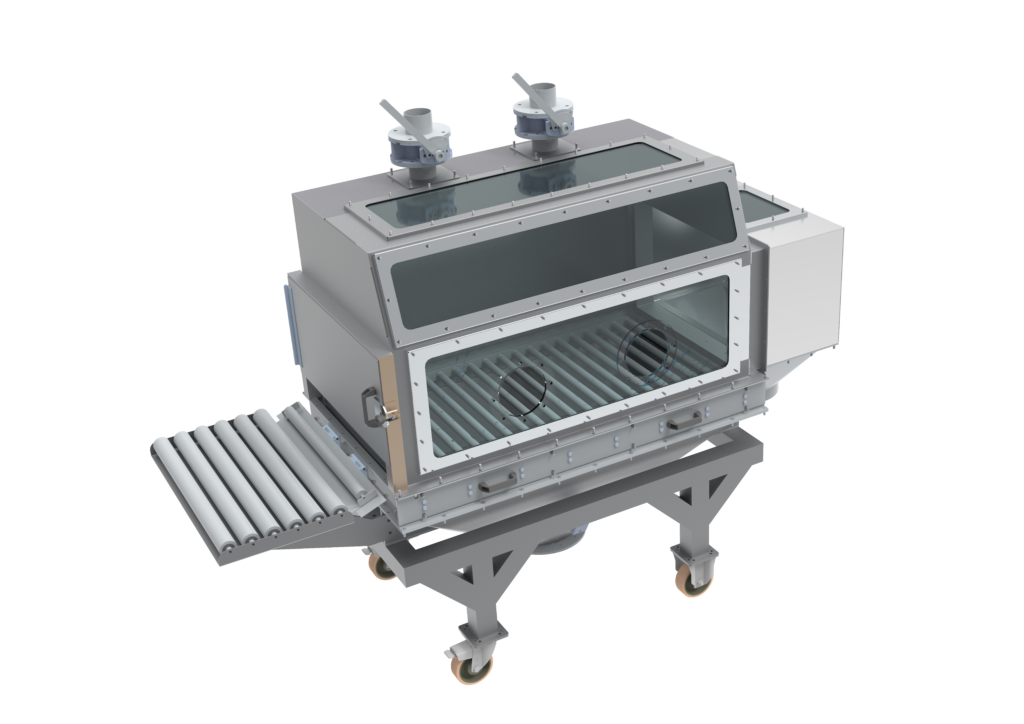

HERMETIC BAG CUTTER

The station is designed for the use of dangerous powders, guaranteeing maximum operator safety. Through an hermetic closing system, operations are carried out using gloves installed in the protection, avoiding any dispersion or direct contact.

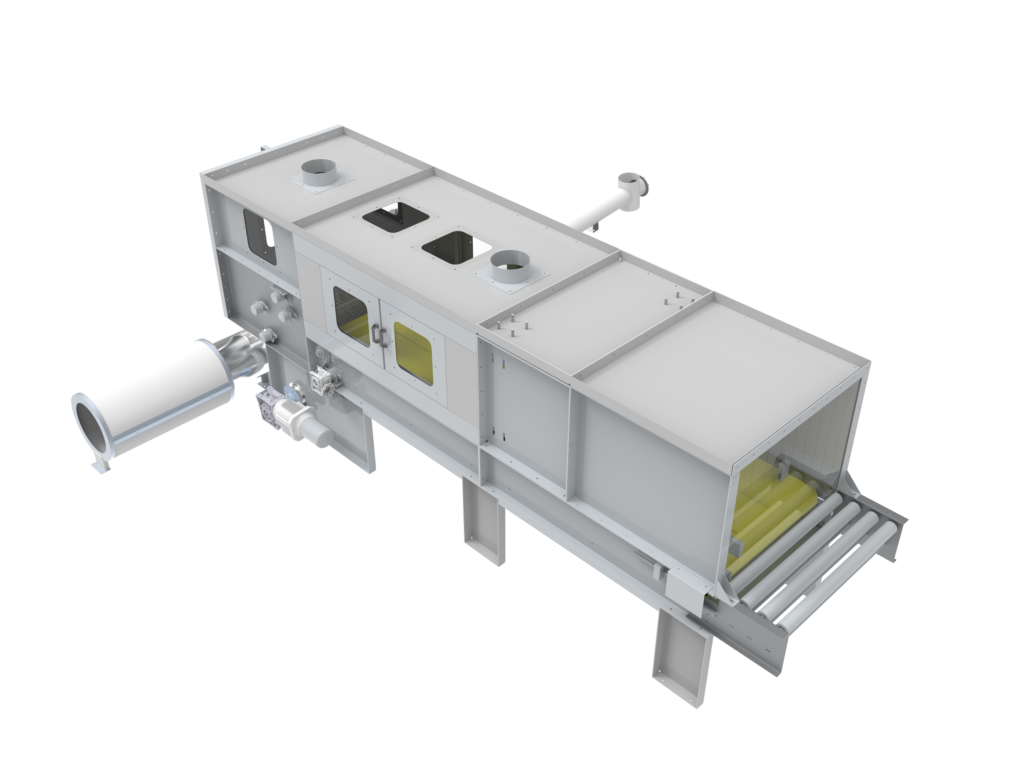

BAG CUTTER WITH SUCTION

Automatic or manual station equipped with a suction system using fans and filters to clean the air from dust. A cleaning process is also provided where the captured material can be reused.

MOBILE BAG CUTTER

It allows the movement of the bag cutter as needed offering the flexibility of a load not tied to a fixed point.

AUTOMATIC BAG CUTTER

The machine uses an automatic blade system to cut the bag and separate the material from everything else. The bags are then compacted by the machine for easy extraction. A screw conveyor feeds the material into the line.

Applications