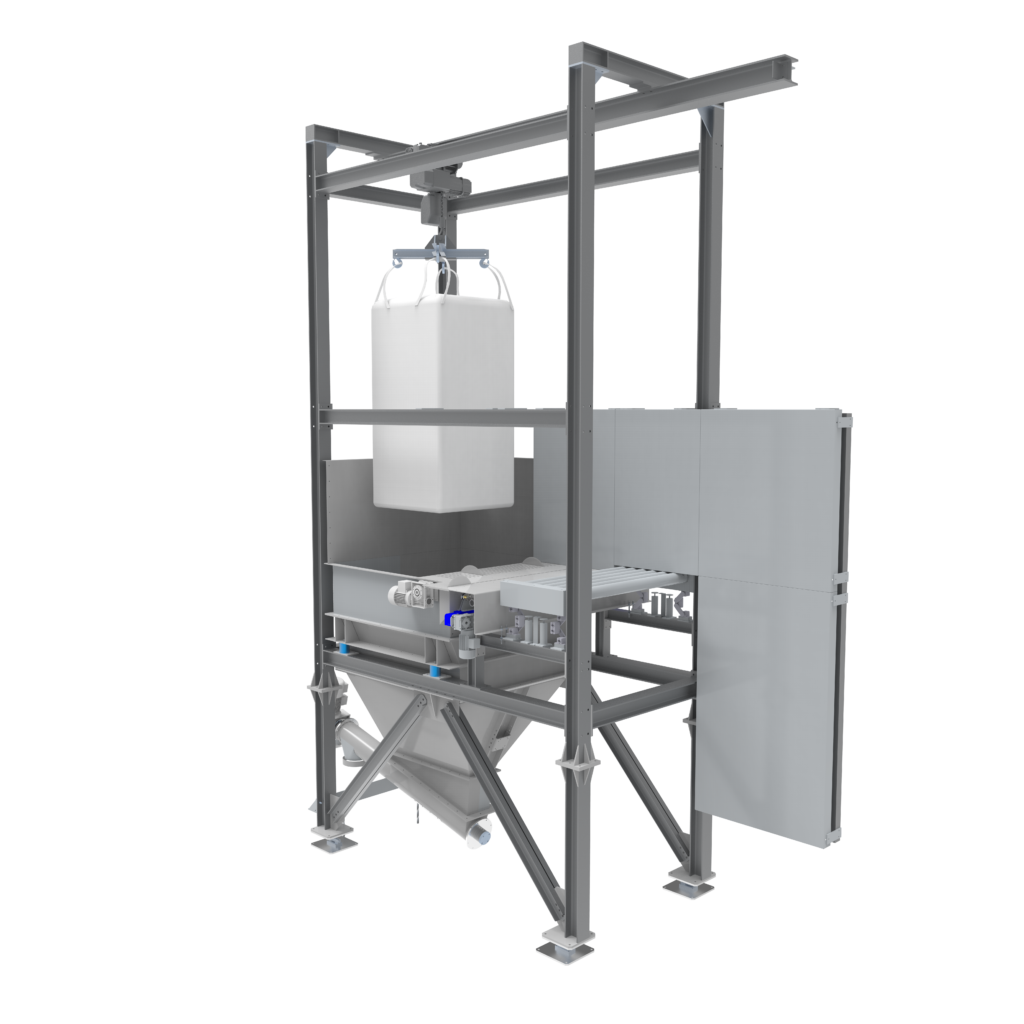

Hiway big-bag unloading stations (FIBC) are designed to safely empty big-bags of up to 2500 kg of different sizes and to reduce the dispersion of dust into the environment, preserving the work area. This equipment consists of sturdy support structures capable of supporting the weight of the big bags which can be inserted using a forklift or hoist lift.

The unloading of the material is facilitated by a receiving platform equipped with pneumatically operated pushers.

The big-bag discharge sleeve is released inside a sealed duct and can be intercepted via a diaphragm valve. It is also possible to use a system of pinching and extension of the sleeve using pneumatic actuators, in order to create a direct unloading duct, avoiding any leakage of the material.

The range of models has been expanded with the addition of a solution equipped with an automatic big-bag cutting and emptying system. Furthermore, the stations can be equipped with a weighing system for controlled material removal. Devices at the base of the big bag are pneumatically operated to help the material flow out of the big bag.

BIG-BAGS UNLOADING STATIONS

EMPTY BIG-BAGS

Hiway big-bag unloading stations (FIBC) are designed to safely empty big-bags of up to 2500 kg of different sizes and to reduce the dispersion of dust into the environment, preserving the work area. This equipment consists of sturdy support structures capable of supporting the weight of the big bags which can be inserted using a forklift or hoist lift.

The unloading of the material is facilitated by a receiving platform equipped with pneumatically operated pushers.

The big-bag discharge sleeve is released inside a sealed duct and can be intercepted via a diaphragm valve. It is also possible to use a system of pinching and extension of the sleeve using pneumatic actuators, in order to create a direct unloading duct, avoiding any leakage of the material.

The range of models has been expanded with the addition of a solution equipped with an automatic big-bag cutting and emptying system. Furthermore, the stations can be equipped with a weighing system for controlled material removal. Devices at the base of the big bag are pneumatically operated to help the material flow out of the big bag.

- Galvanized carbon steel

- AISI 304 or AISI 316 stainless steel

- In accordance with the customer’s needs

MAIN LAYOUTS

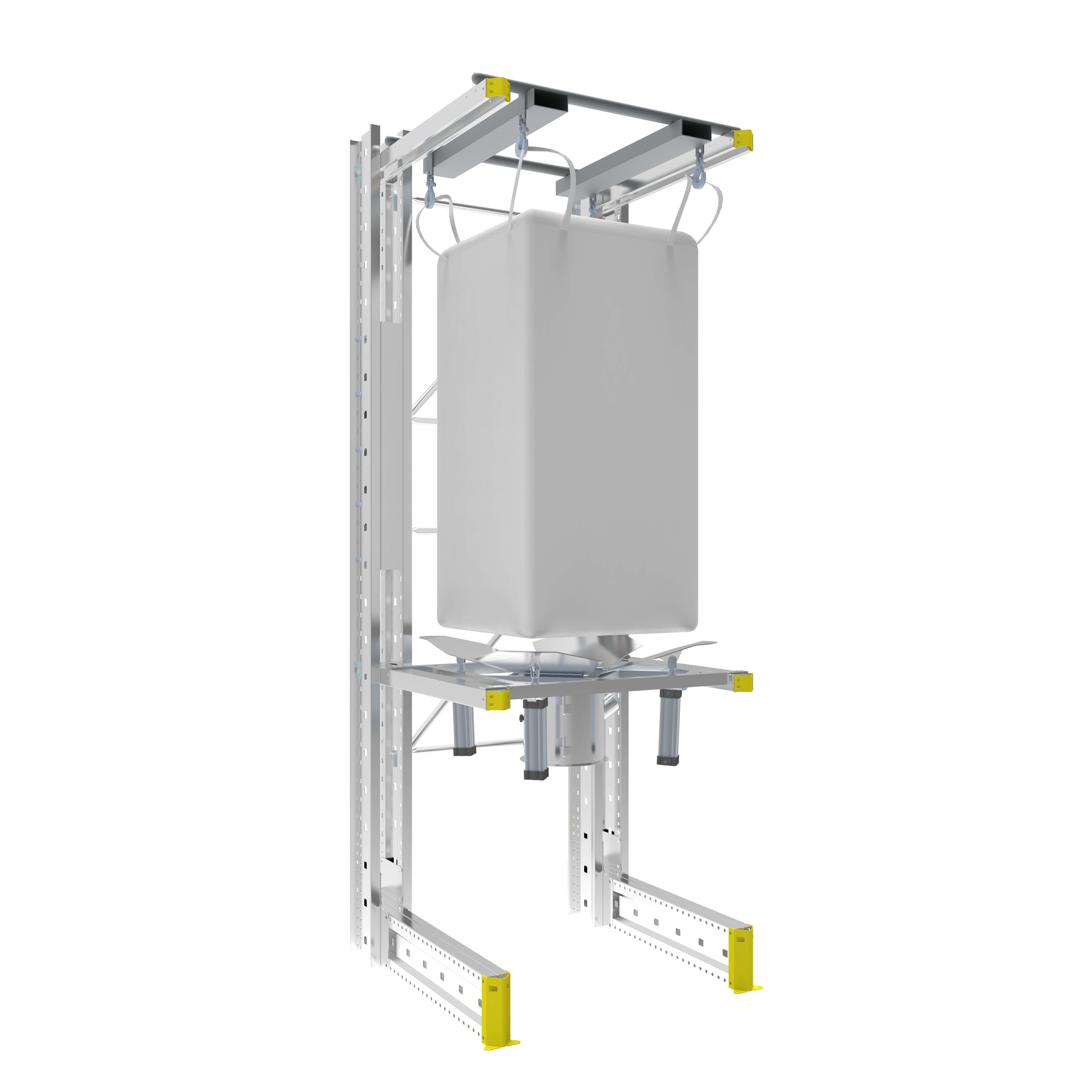

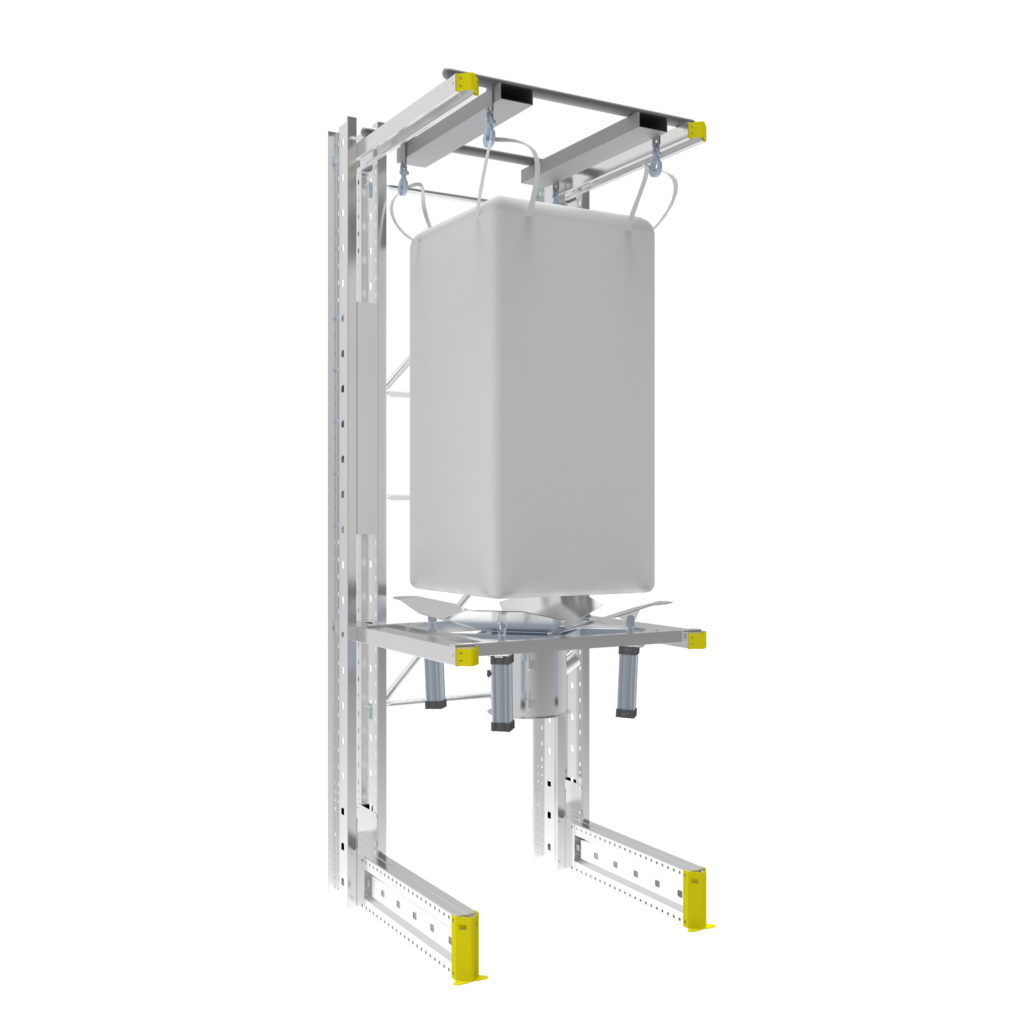

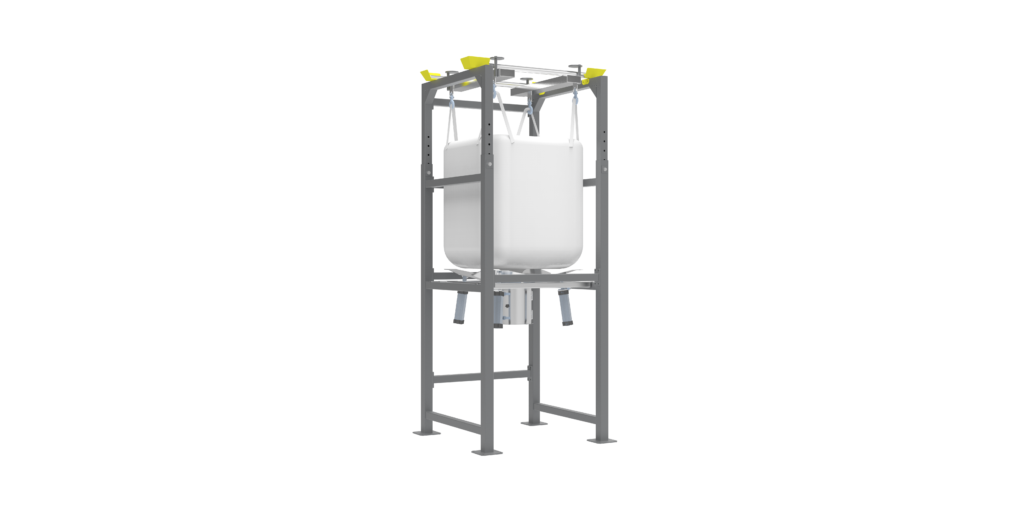

MODULAR WITH ADJUSTABLE CANTILEVER CONSOLES

Structure with the ability to be height- adjustable that combines accessibility and practicality.

MONOLITHIC WITH LIFTING WINCH

The lifting and movement of the big bag are done automatically using a winch operated by a control panel.

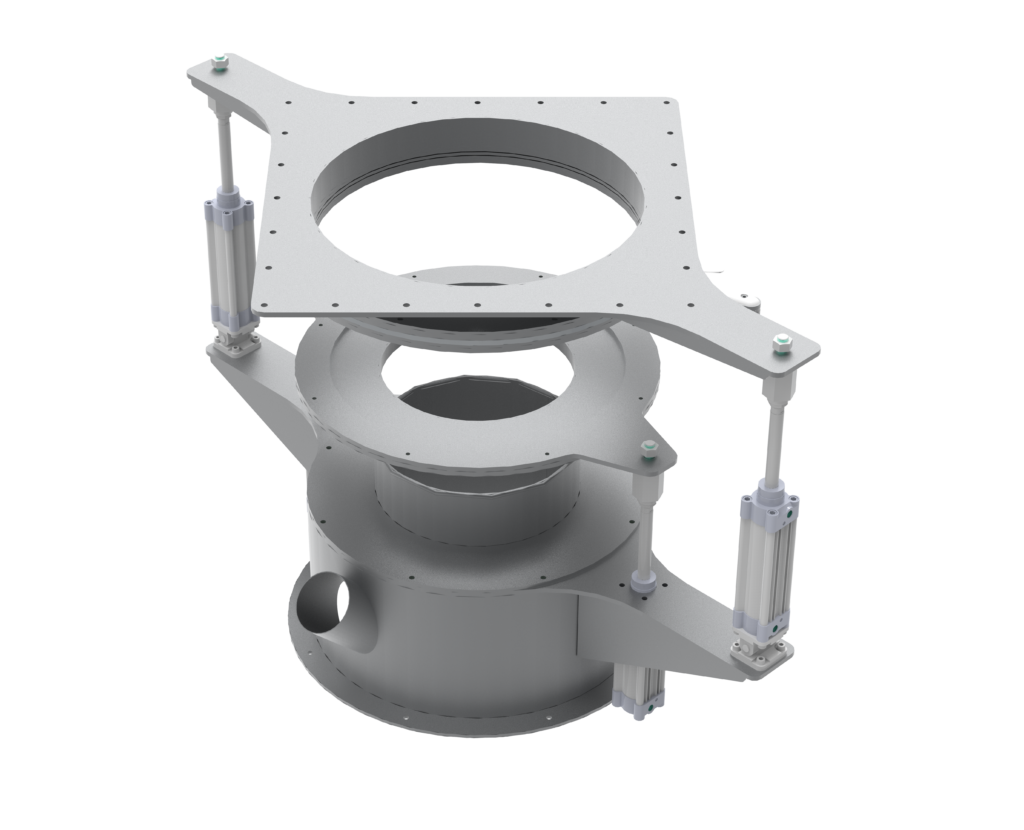

AUTOMATIC CUTTING STATION

Thanks to a hoist, the big bag is loaded from distance by the operator and positioned in the place where an automatic linear cut is made to open the sack.

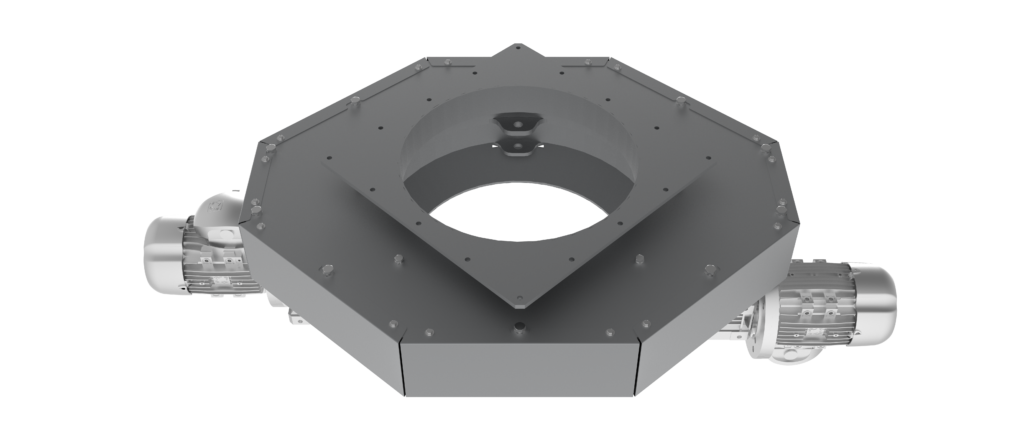

COMPLETELY AUTOMATIC STATION

Possibility of loading big bags into the structure using both a forklift and a hoist. Once in position, A circular automatic cut is safely initiated, along with a lowering of the underlying platform to facilitate the material discharge. Finally, a breaker facilitates access into the line.

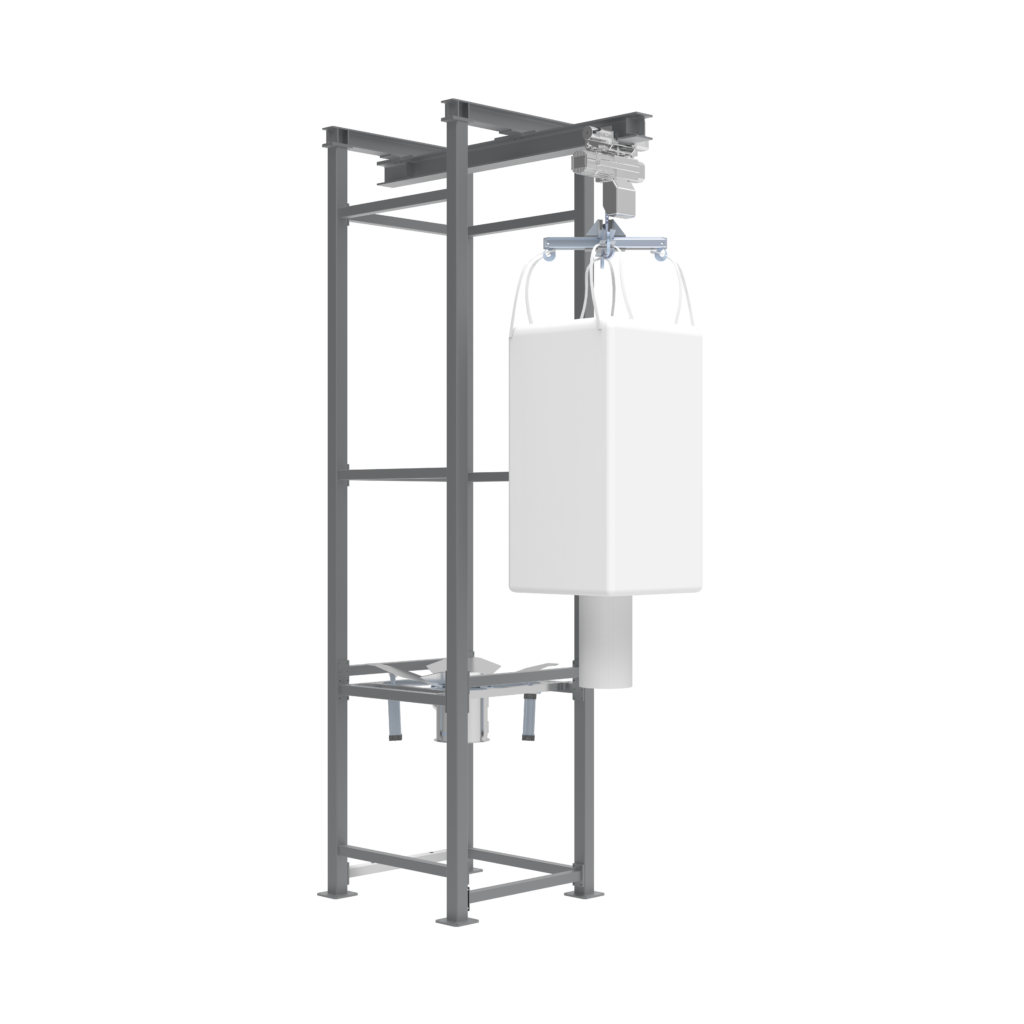

HEIGHT-ADJUSTABLE TELESCOPIC

The big bags are loaded with the forklift, and the operator can load bags of various sizes and weights due to the sturdy structure that can be adjusted in height.

MOBILE BIG-BAG EMPTYING STATION

A mobile station that allows the emptying of big bags at any point without restrictions, with the addition of a small TVE line for material discharge material.

MAIN COMPONENTS

Accessories

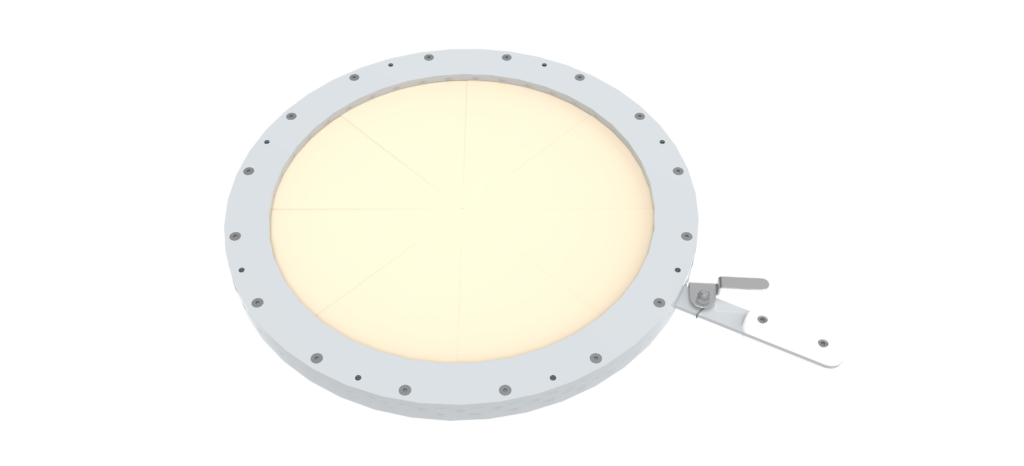

MANUAL DIAPHRAGM VALVE

By manually rotating the lever, the operator has the possibility of closing the big bag.

AUTOMATIC DIAPHRAGM VALVE FOR BIG-BAG CLOSURE

It allows the operator, through an electrical panel, to close the big bag unloader.

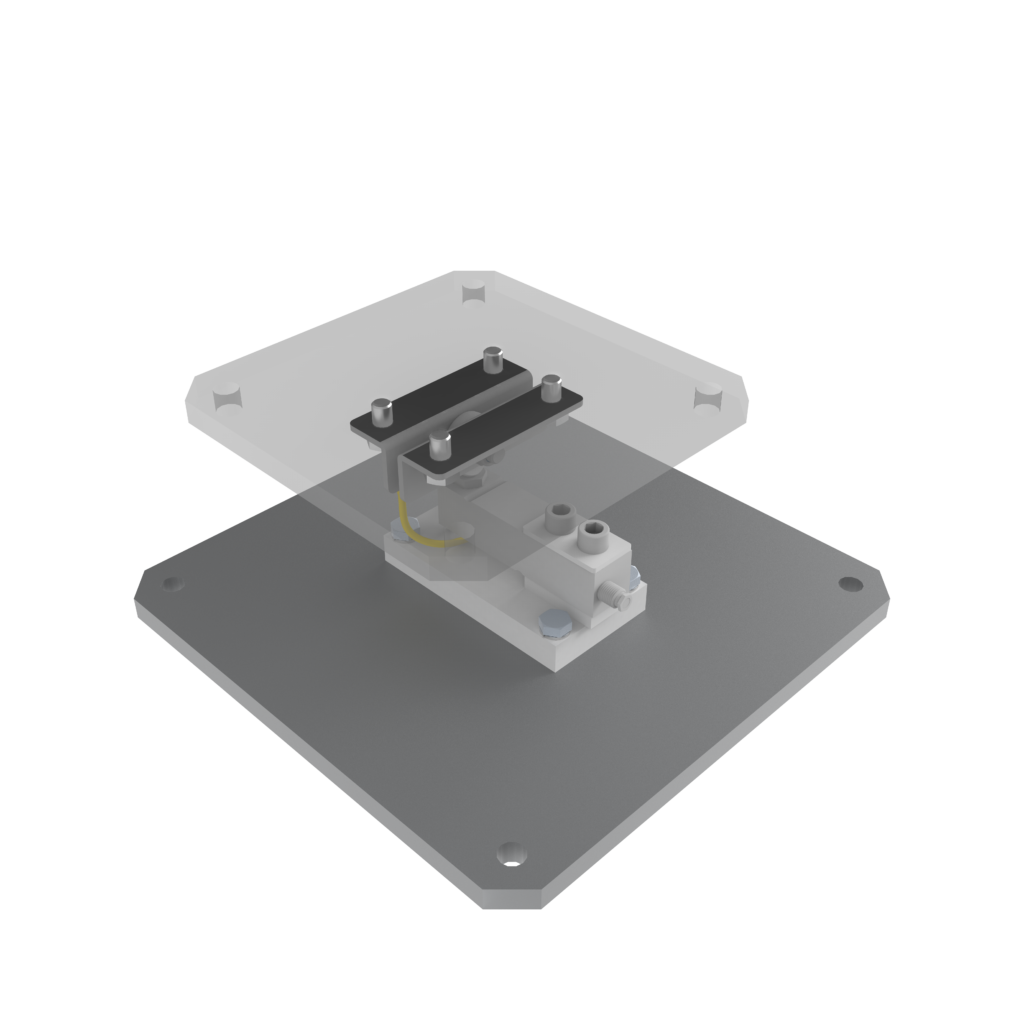

SLEEVE TENSIONER

Pneumatically operated device controlled by the operator for gripping and tensioning the sleeve of the bag, facilitating the material discharge.

LOAD CELLS

Thanks to the connection with the electrical panel, it allows for weighing the quantities of material to be introduced into the circuit.

Applications