Aero-mechanical conveyor

Hiway aero-mechanical conveyors are ideal for the transportation of bulk materials, both in powder and granules. The high linear speed imparted to the discs generates a movement of air that fluidifies the material, allowing easy transport, without mixing it and preserving its integrity. These systems are essential and light with excellent efficiency thanks to the use of low energy powers too. This line of conveyors is particularly suitable for the transportation of material at high heights, even over 20 metres, or for applications that require high transport capacity.

This line of conveyors is particularly suitable for transporting material at high heights, even up to 20 meters, or for applications that require a high transport capacity.

[TVE]

Aero-mechanical conveyor

qualità e innovazione

Hiway aero-mechanical conveyors are ideal for the transport of loose materials, both in powder and granules. The high linear speed imparted to the discs generates a movement of air that fluidizes the

material, allowing easy transport, without mixing it and preserving its integrity. These systems are essential and light with excellent efficiency thanks also to the use of low energy powers.

This line of conveyors is particularly suitable for transporting material at high heights, even up to 20 meters, or for applications that require a high transport capacity.

tve

Main Construction Materials

- Carbon steel

- AISI 304 or AISI 316 stainless steel

- Tempered iron

- AISI 304 or AISI 316 stainless steel

- Galvanized carbon steel

- Stainless steel

- Carbon steel

- AISI 304 or AISI 316 stainless steel

- Hytrel

- Glass filled nylon

- In accordance with the needs

Technical Specification

Main layouts

also ATEX

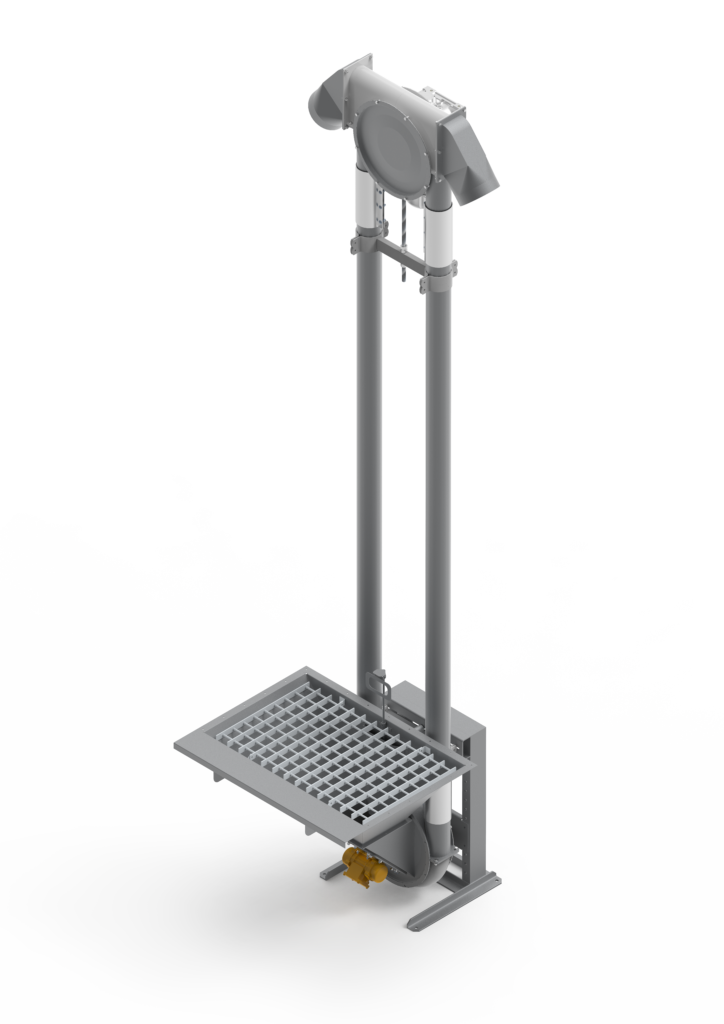

TVE-CV

Vertical

The rational design guarantees the system efficiency and versatility thanks to the possibility of orientating the conveyor from 0° to 90°.

TVE-COV

Horizontal/Vertical

The configuration of the tubes with one first horizontal section and the second vertical section (or vice versa) can have multiple inlets and one single outlet. The pipes can be placed side by side horizontally or vertically.

TVE-BCV

Vertical bidirectional

With this solution, two users can be powered by simply reversing the rotation of the motor.

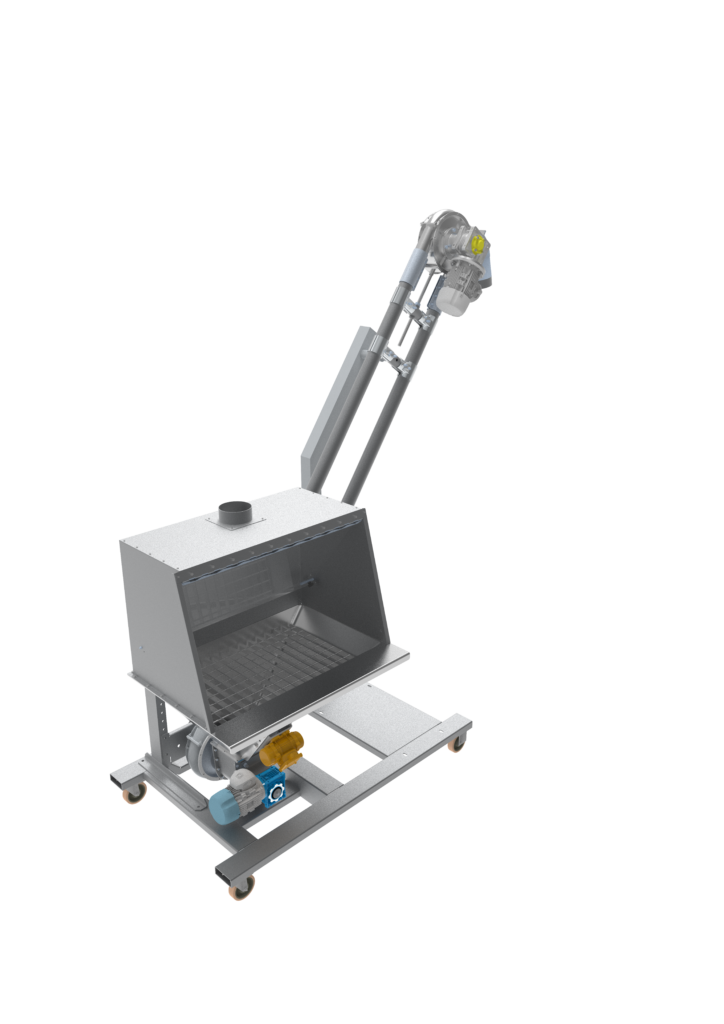

MOBILE TVE

Option that allows to easily move a small aero-mechanical conveyor to various positions without the need to fix it in a single place.

MAIN COMPONENTS

Components

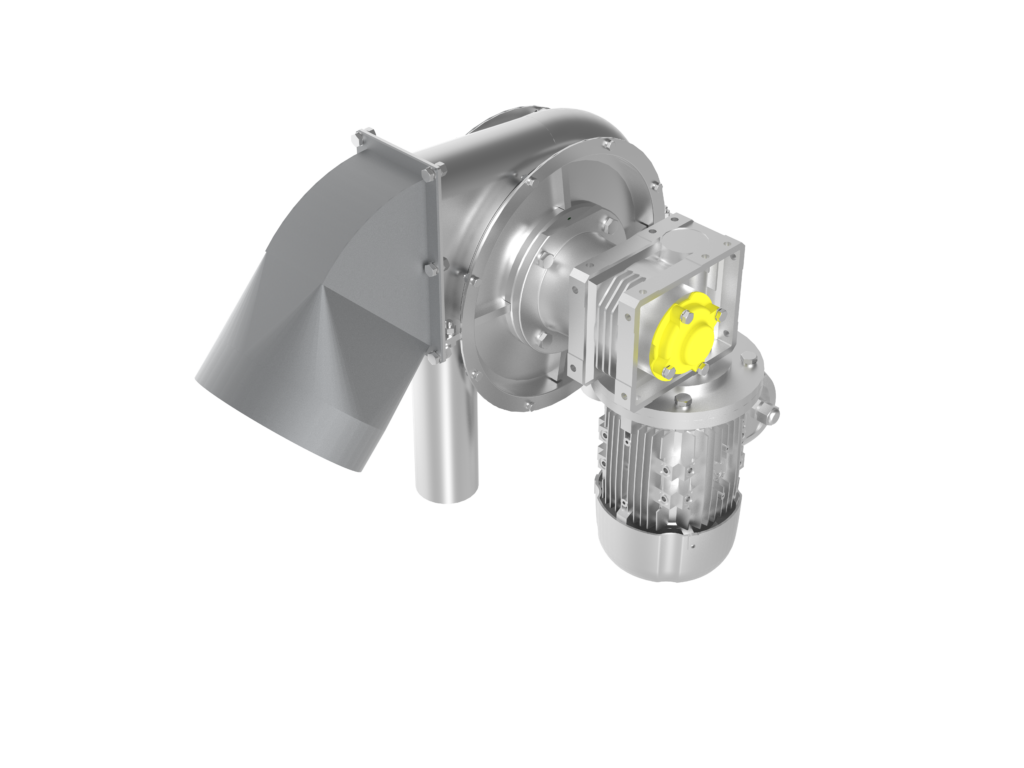

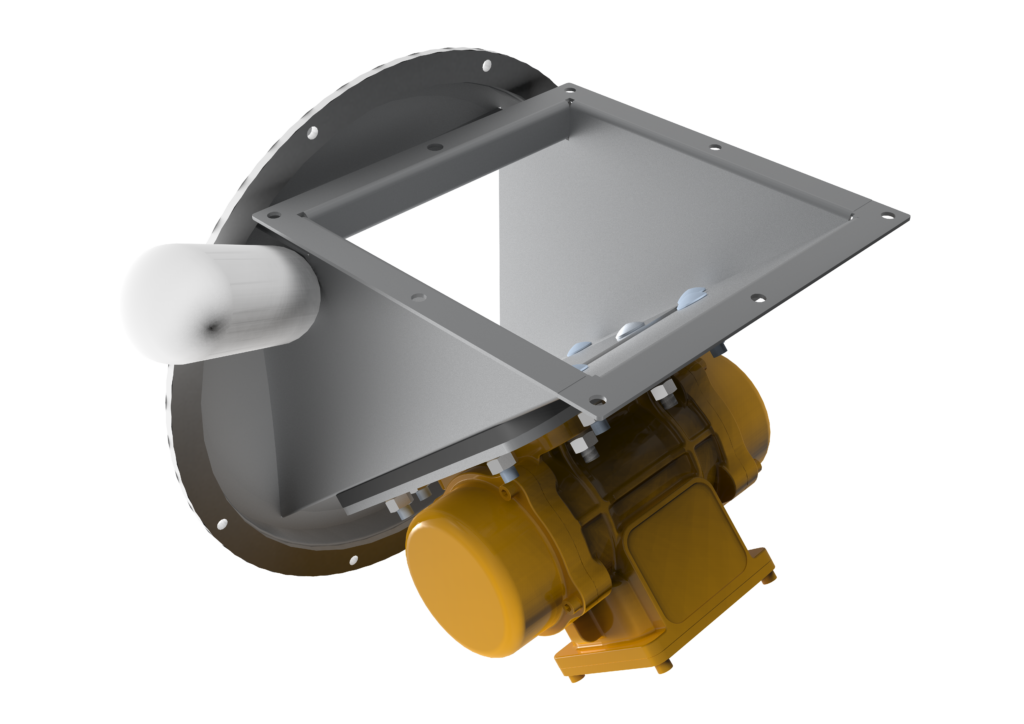

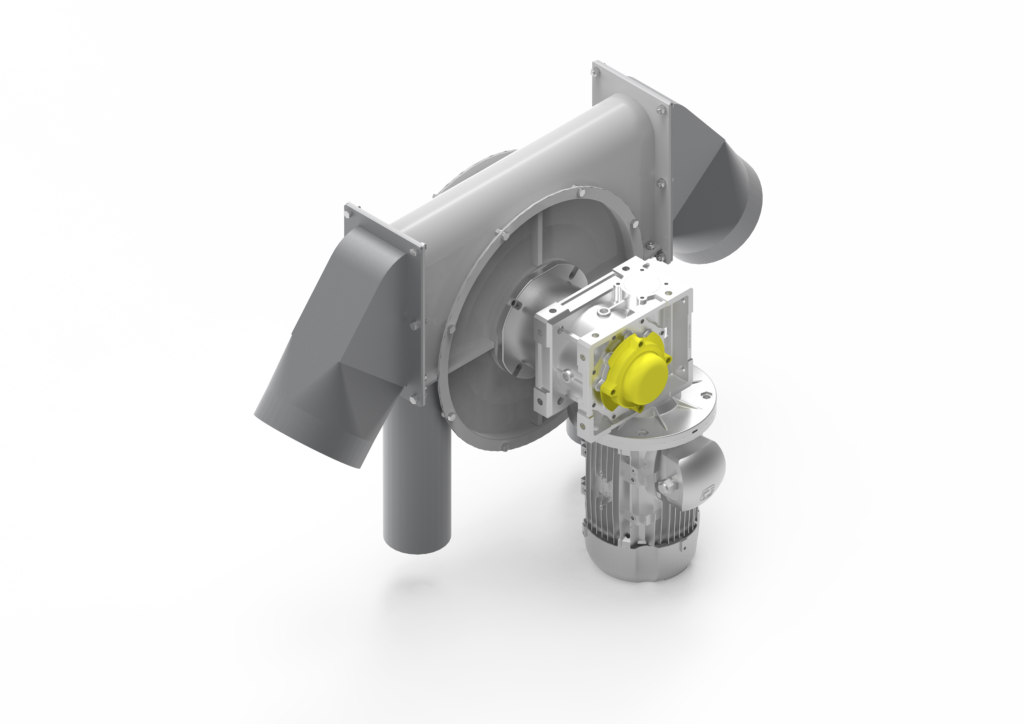

MOTOR DRIVEN CORNER

Moves the rope in the system.

RETURN CORNER

It allows the loop closure of the circuit.

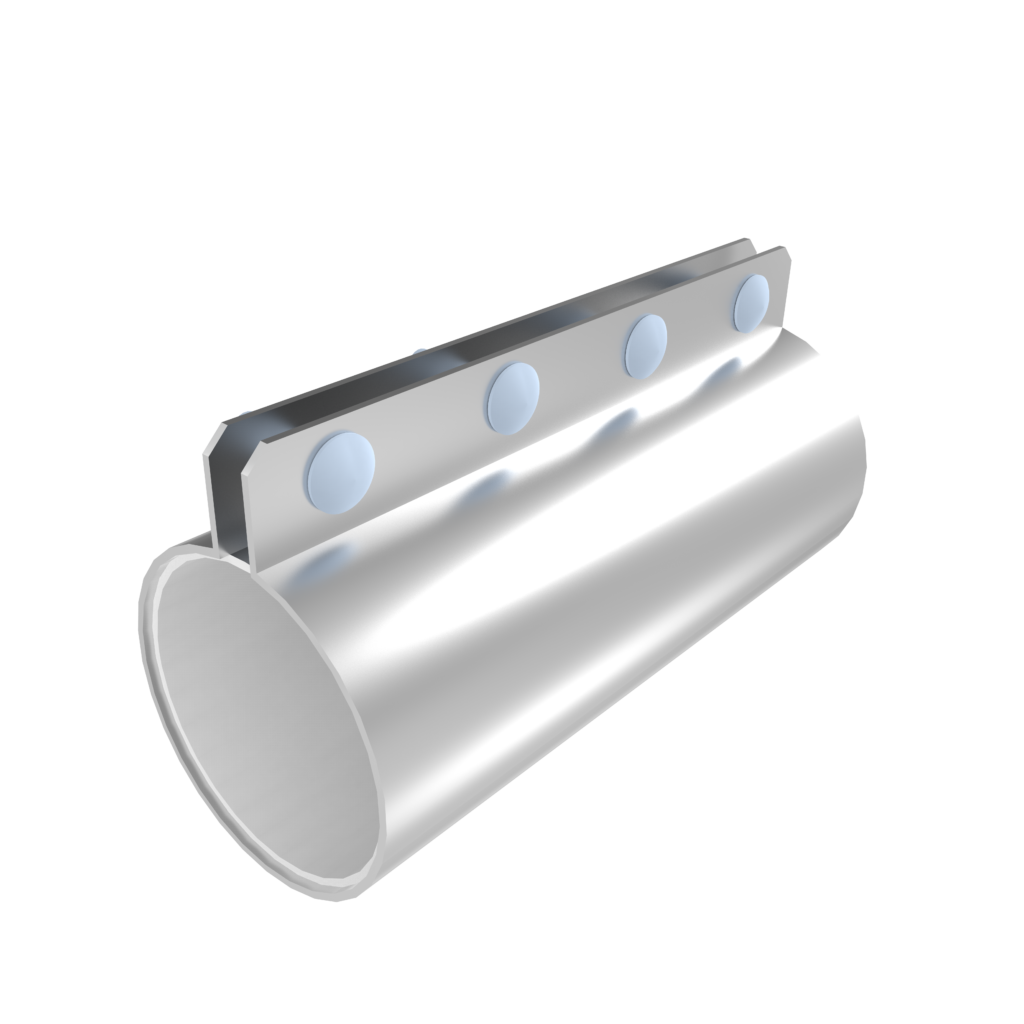

TUBE JOINT

They are quick to install and guarantee the robustness of the connection as well as the prevention of dust escaping into the environment and electrical continuity for earthing.

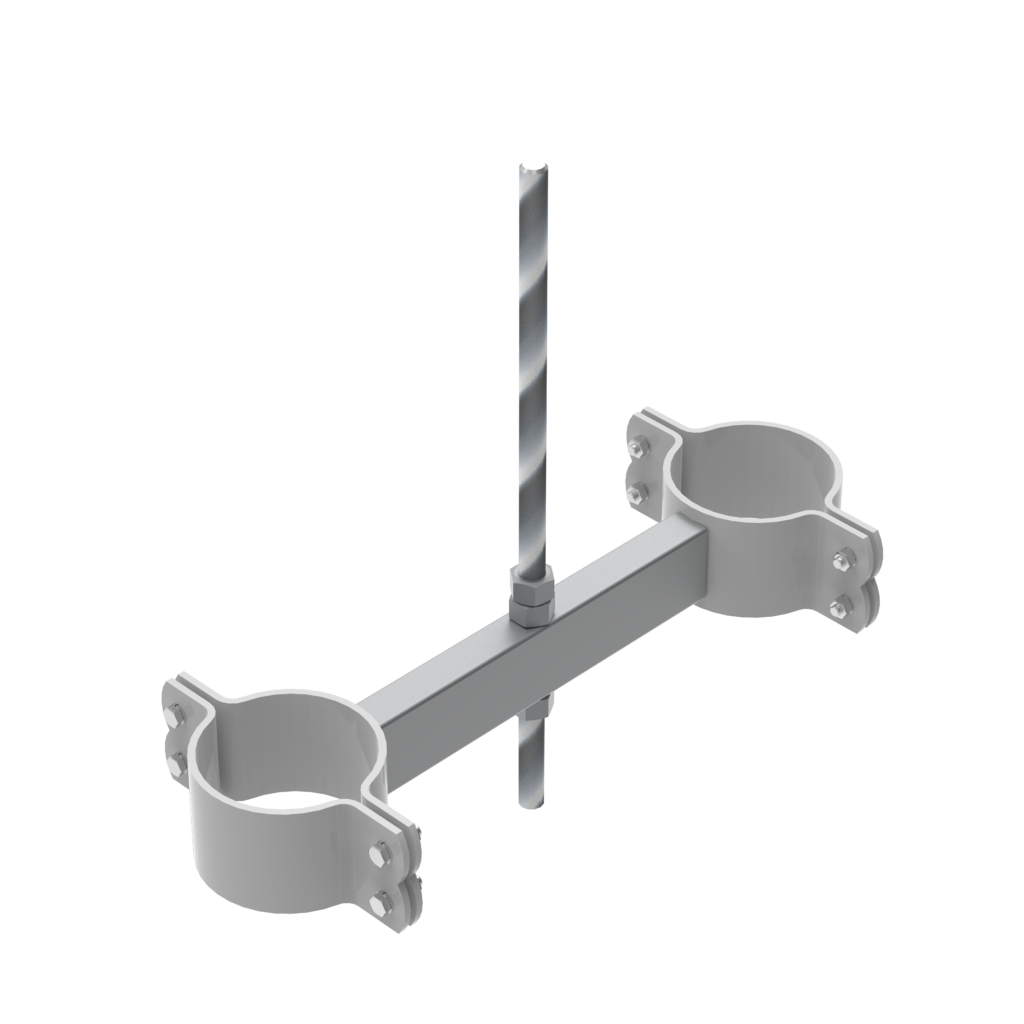

TENSIONER

Manual or automatic device that allows the rope to always remain tensioned at the right point.

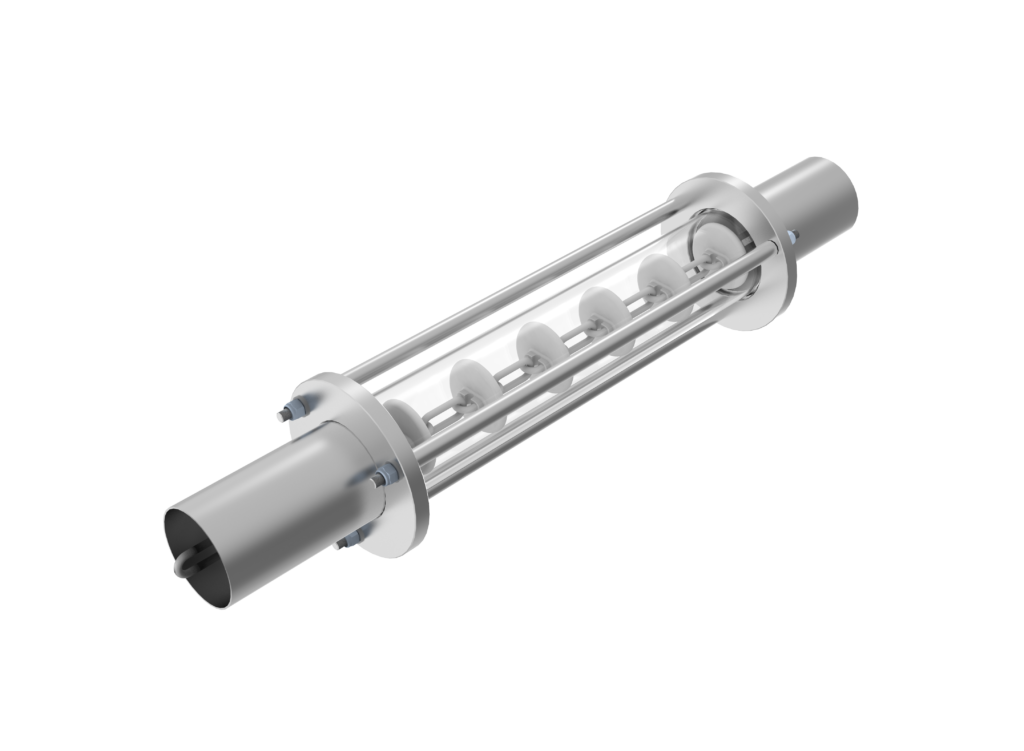

SIGHT GLASS

Optional transparent tube section to allow inspection of the rope or chain inside the line.

Load

VIBRATED INLET

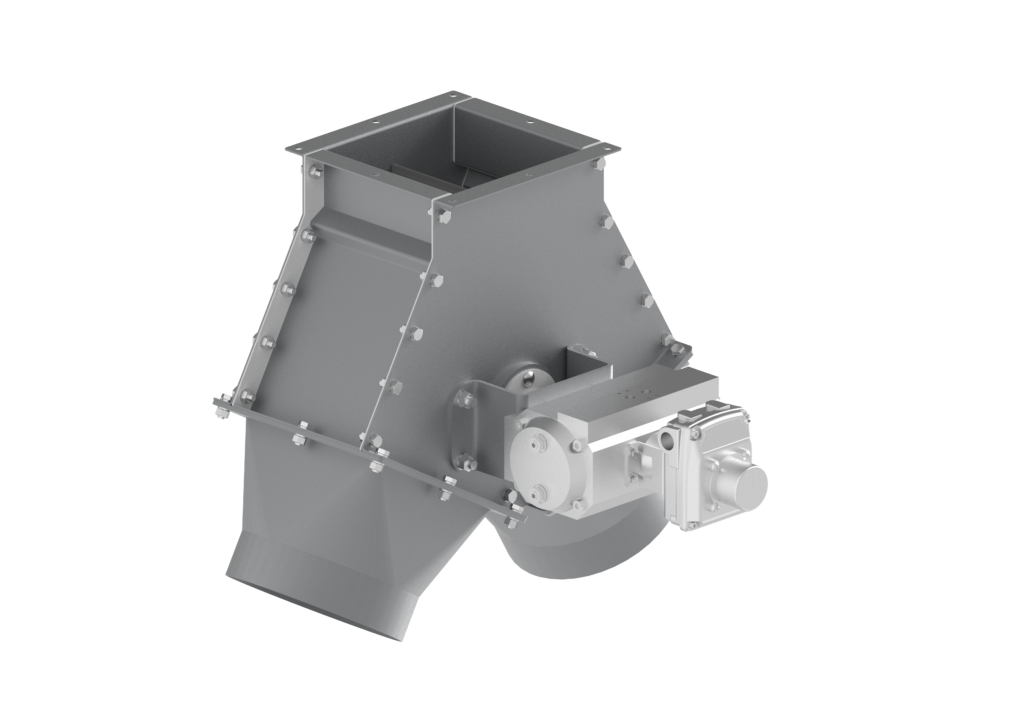

Specific hopper inlet with an integrated vibration mechanism.

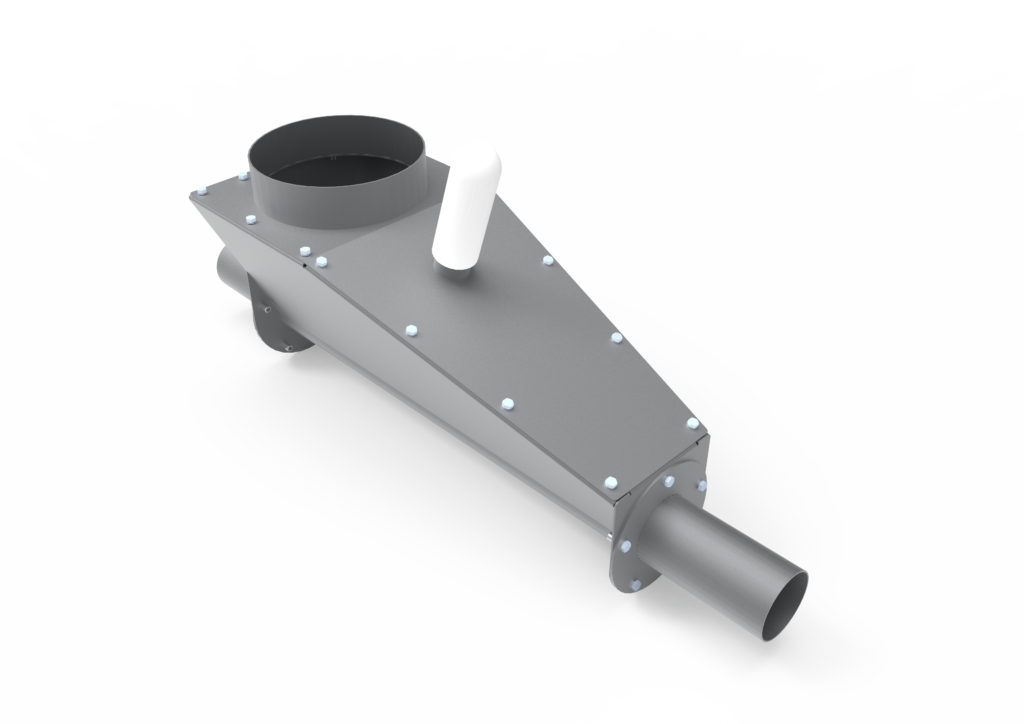

LOADING SPOUT (LHG)

Simple and flexible gravity inlet, suitable for all conveyors.

Unload

DISCHARGE CORNER

Curve that unloads the material due to the centrifugal force.

CORNER WITH DOUBLE DISCHARGE

Corner equipped with double discharge (right and left) to alternatively release the material by changing the direction of rotation of the rope.

Accessories

DIVERTER VALVE

Pneumatically operated valve that directs the material in one or the other direction.

CORNER WITH QUICK OPENING

Corner equipped with quick opening without screws for inspection and cleaning.

Applications